Ultimate Guide to Rolling Forming Machines

By:Admin

The SR Series Rolling Forming Machine is equipped with advanced features that make it stand out in the market. With its high-speed rolling and forming capabilities, this machine is able to produce a wide range of metal products with minimal material waste and maximum accuracy. It is also designed to be user-friendly, with intuitive controls and easy maintenance, making it suitable for both experienced professionals and newcomers to the industry.

The company behind the SR Series Rolling Forming Machine, Stud Rolling Forming Machine, has a strong reputation in the metal forming industry. With over 20 years of experience, they have become a trusted name in the market, known for their commitment to quality, reliability, and customer satisfaction. Their team of skilled engineers and technicians are dedicated to pushing the boundaries of metal forming technology, and the SR Series Rolling Forming Machine is a testament to their innovative spirit.

In addition to their technical expertise, Stud Rolling Forming Machine is also known for their exceptional customer support and after-sales service. They understand the unique needs of their clients and offer personalized solutions that meet their specific requirements. This commitment to customer satisfaction has earned them a loyal customer base, and the release of the SR Series Rolling Forming Machine is expected to further solidify their position as a leading provider of metal forming equipment.

The SR Series Rolling Forming Machine is set to have a significant impact on the metal forming industry. Its ability to streamline the production process and reduce material waste will not only benefit manufacturers, but also contribute to a more sustainable and cost-effective manufacturing industry. The machine's versatility and precision make it suitable for a wide range of applications, from automotive and aerospace to construction and infrastructure development.

As the global demand for metal products continues to grow, the SR Series Rolling Forming Machine is poised to become an essential tool for manufacturers looking to stay ahead of the competition. Its cutting-edge technology and efficiency will allow companies to increase their production capacity and improve their bottom line, while maintaining the high quality standards that customers expect. With the support of Stud Rolling Forming Machine's experienced team, clients can be confident that they are investing in a reliable and innovative solution for their metal forming needs.

In conclusion, the release of the SR Series Rolling Forming Machine marks a new chapter in the evolution of metal forming technology. Stud Rolling Forming Machine's dedication to innovation, quality, and customer satisfaction has resulted in a machine that is set to redefine the industry standards. With its advanced features and user-friendly design, the SR Series Rolling Forming Machine is well-positioned to become a game-changer in the metal forming industry, providing manufacturers with the tools they need to succeed in an increasingly competitive market.

Company News & Blog

High-quality roll forming machine for efficient production

Manufacturing process is an essential aspect of various industries. From construction to automotive, the need for efficient and precise manufacturing equipment is always in demand. In this regard, the introduction of the Upright Roll Forming Machine by a leading company has revolutionized the industry, offering innovative solutions for a wide range of manufacturing requirements.The Upright Roll Forming Machine is a versatile piece of equipment that is designed to efficiently produce a wide variety of metal parts and components. It is used in various industries such as automotive, construction, aerospace, and many others. The machine incorporates advanced technology and features, making it a valuable asset for manufacturers seeking to enhance their production capabilities.The Upright Roll Forming Machine is renowned for its high precision, speed, and efficiency. It can create parts with complex shapes and designs, ensuring that the final product meets the required specifications. This level of accuracy is crucial for industries where precision is of utmost importance, such as the automotive and aerospace sectors.The machine is also known for its flexibility, allowing manufacturers to produce a wide range of components using different types of materials. This versatility is invaluable for businesses that need to adapt to changing market demands and explore new opportunities in various industries.One of the most significant advantages of the Upright Roll Forming Machine is its ability to streamline the manufacturing process, reducing both time and cost. This is achieved through its high-speed production capabilities, minimizing downtime and maximizing output. As a result, businesses can benefit from increased efficiency and productivity, ultimately leading to improved profitability.In addition to its impressive performance, the Upright Roll Forming Machine also prioritizes safety and ease of use. The machine is equipped with advanced safety features to ensure a secure working environment for operators. Furthermore, it is designed with user-friendly controls and interfaces, making it accessible for a wide range of operators, including those with minimal experience.The company behind the Upright Roll Forming Machine has a proven track record of delivering high-quality manufacturing equipment. With years of experience and expertise in the industry, they have established themselves as a reliable and innovative provider of machinery solutions. Their commitment to excellence and continuous improvement is reflected in the design and performance of the Upright Roll Forming Machine.The company's dedication to customer satisfaction is evident through their comprehensive support services. They offer tailored solutions to meet the specific needs of each client, ensuring that they can maximize the benefits of the Upright Roll Forming Machine. From installation and training to maintenance and technical support, the company provides a complete package to ensure that their customers can seamlessly integrate the machine into their operations.Overall, the introduction of the Upright Roll Forming Machine by {company name} represents a significant advancement in the manufacturing industry. Its innovative design, advanced features, and proven performance make it a game-changer for businesses seeking to enhance their manufacturing capabilities. With its ability to deliver high precision, efficiency, and flexibility, the machine is set to empower manufacturers across various industries, driving productivity and competitiveness.

CNC Aluminum Profile: Tips for Affordable and Quality Aluminum Profiles

Title: Revolutionary Cnc Aluminum Profile Taking Manufacturing Efficiency to New HeightsIntroduction:In a breakthrough development, a leading manufacturing company has recently unveiled its cutting-edge Cnc Aluminum Profile, designed to transform the industrial sector with its unmatched precision, durability, and efficiency. This innovative product is set to revolutionize manufacturing processes across various industries, ensuring higher productivity and superior quality fabrication.Unveiling the Cnc Aluminum Profile:The Cnc Aluminum Profile, developed by the forward-thinking engineers at (company name), is a result of intensive research and testing. This ground-breaking technology offers a wide range of advantages that will redefine the manufacturing landscape. With a focus on precision, reliability, and longevity, the Cnc Aluminum Profile is set to elevate industrial operations to new levels of performance.Unmatched Precision:The Cnc Aluminum Profile boasts precision engineering that allows for highly accurate and intricate cutting, shaping, and machining operations. The profile’s advanced computer numerical control (CNC) mechanism ensures millimeter-level precision, reducing human error and minimizing wastage. With this exceptional precision, manufacturers will witness a significant improvement in product quality and consistency.Enhanced Durability:Manufacturers often face the challenge of keeping manufacturing equipment operational and efficient for extended periods. The Cnc Aluminum Profile addresses this concern with its construction using high-grade aluminum alloy, capable of withstanding high stress levels and continuous usage. This superior durability ensures extended equipment lifespan, reducing maintenance costs and downtime for businesses.Improved Efficiency:One of the key highlights of the Cnc Aluminum Profile is its ability to streamline and enhance manufacturing processes. With computer-controlled algorithms, this technology significantly reduces manual labor, resulting in improved operational efficiency and reduced time-to-market. The profile’s high-speed machining capability allows for faster production cycles, increasing productivity and overall output.Versatility Across Industries:The versatility of the Cnc Aluminum Profile makes it suitable for various industries ranging from automotive and aerospace to construction and consumer goods. The profile’s adaptability to different manufacturing requirements and specifications ensures it can be seamlessly integrated into existing production lines, facilitating smooth transitions without disrupting the manufacturing workflow.Sustainable Manufacturing:In addition to its significant advantages in productivity and quality, the Cnc Aluminum Profile embraces sustainability in manufacturing. The profile's energy-efficient design reduces power consumption and minimizes environmental impact. Additionally, the technology's precise material utilization minimizes waste, making it an eco-friendly solution to drive sustainable manufacturing practices globally.Implementation in Manufacturing Companies:Several prominent manufacturing companies have already begun integrating the Cnc Aluminum Profile into their production processes. Initial results have been overwhelmingly positive, demonstrating improved operational efficiency, higher product quality, and increased profitability. The successful implementation of this technology further underscores the potential benefits it can bring to companies across industries.Conclusion:The introduction of the Cnc Aluminum Profile represents a paradigm shift in the manufacturing sector. Its precision, durability, and efficiency make it a game-changing technology that promises to optimize production processes, increase output, and elevate product quality. With its versatility and adaptability, the Cnc Aluminum Profile is set to become an integral part of manufacturing operations worldwide, cementing its position as a catalyst for innovation and progress in the industrial landscape.

Roll Forming Machines for Drywall and House Making: Metal Studs, Tracks and Dumplings

and Roll Forming Equipment.Metal Roof Roll Machine For Drywall – Top Quality House Making MachineIf you are looking for a top-quality house making machine, look no further than the metal roof roll machine for drywall. This versatile machine is capable of producing all the components needed for constructing a sturdy, reliable house, including metal studs, tracks, roofing, and more.One of the primary advantages of the metal roof roll machine for drywall is its ability to generate metal studs and tracks using a specialized technique known as roll forming. In this technique, sheets of metal are fed through a series of rollers that gradually bend the metal into the desired shape. This produces a durable, strong, and uniform product that is perfectly suited for use in residential and commercial construction.The metal stud and track roll forming machine from Alibaba is an excellent example of this type of equipment. It is capable of producing high-quality metal studs and tracks in a variety of sizes and configurations, making it suitable for a wide range of construction applications. Whether you are building a small residential property or a large commercial complex, this machine can help you create the perfect metal framing to get the job done.Other Benefits of Steel FramingIn addition to being strong, durable, and reliable, steel framing also offers a number of other advantages for construction projects. For example, steel is much lighter than traditional building materials like bricks and concrete, which can help reduce the overall weight of a building and make it easier to erect. It is also non-combustible, which can help reduce the risk of fires in buildings.Steel framing is also extremely flexible, allowing contractors to create customized designs and incorporate a wide range of materials and finishes into their projects. And because it is produced using sophisticated manufacturing processes like roll forming, it is possible to create extremely precise, uniform components that are easy to install and require very little maintenance.Finding the Right Metal Stud Making MachineIf you are interested in using roll forming equipment to produce metal studs and tracks for your construction projects, it is important to choose the right machine for your needs. Look for equipment that offers a high level of precision and flexibility, and that is capable of producing a wide range of different shapes and sizes.Also, be sure to choose a machine that is backed by a reputable manufacturer with a track record of producing high-quality equipment. This will ensure that you receive reliable, long-lasting equipment that meets your needs and exceeds your expectations.ConclusionOverall, the metal roof roll machine for drywall is a top-quality house making machine that is capable of producing a wide range of components for any construction project. Whether you are constructing a single-family home or a large commercial complex, this equipment is the perfect tool for ensuring that your building is strong, durable, and reliable. So if you are in the market for a metal stud making machine or roll forming equipment, look no further than the metal roof roll machine for drywall – the best choice for your construction needs!

Steel Roll Forming Machine Factory Offers High-Quality Color Steel Roll Forming Machines

Color Steel Roll Forming Machine Factory, a leading manufacturer of roll forming machines, has recently announced the launch of their new line of machines aimed at revolutionizing the steel forming industry. With a focus on innovation and advanced technology, the company aims to provide state-of-the-art solutions to meet the needs of their clients and the market demand for high-quality steel products.The factory, located in [location], is equipped with advanced manufacturing facilities and a team of expert engineers and technicians with years of experience in the industry. The company specializes in the design and production of a wide range of roll forming machines, including but not limited to, roofing sheet roll forming machines, wall panel roll forming machines, and corrugated sheet roll forming machines. With a focus on precision and efficiency, Color Steel Roll Forming Machine Factory is able to provide custom solutions to meet the specific requirements of their clients.One of the key features that set Color Steel Roll Forming Machine Factory apart from other manufacturers is their commitment to using high-quality materials and components in their machines. This ensures the durability and reliability of the machines, resulting in higher productivity and lower maintenance costs for their clients. In addition, the company also places a strong emphasis on incorporating the latest technological advancements in their machines, such as computerized controls and automation systems, to further improve performance and efficiency.In order to maintain their position as a leading manufacturer in the industry, Color Steel Roll Forming Machine Factory regularly invests in research and development to stay ahead of market trends and technological advancements. This allows them to continuously improve their product offerings and introduce new and innovative solutions to their clients. The company also takes customer feedback seriously and uses it to drive their product development efforts, ensuring that they are able to deliver machines that meet and exceed the expectations of their clients.Furthermore, Color Steel Roll Forming Machine Factory is also committed to providing excellent customer service and support. They understand the importance of providing comprehensive training and technical support to their clients, ensuring that they are able to operate and maintain their machines effectively. The company also offers a range of after-sales services, including maintenance and repair services, to ensure the long-term performance and reliability of their machines.In addition to their focus on product quality and customer satisfaction, Color Steel Roll Forming Machine Factory also places a strong emphasis on sustainability and environmental responsibility. The company is dedicated to minimizing their environmental impact through the use of energy-efficient manufacturing processes and the responsible sourcing of materials. They also strive to design their machines in a way that minimizes waste and maximizes resource efficiency.As the market for steel products continues to grow, Color Steel Roll Forming Machine Factory is well-positioned to meet the increasing demand for high-quality roll forming machines. With their commitment to innovation, quality, and customer satisfaction, the company is poised to continue leading the industry and setting new standards for excellence.For more information about Color Steel Roll Forming Machine Factory and their range of roll forming machines, visit their website [website URL] or contact their sales team at [contact information].

Advanced Roll Forming Machine for Colored Metal Steel Sheets

Title: Innovative Colored Metal Steel Sheet Roll Forming Machine Poised to Revolutionize the Construction IndustryIntroduction:In a significant technological breakthrough, a leading manufacturing company has unveiled a cutting-edge Colored Metal Steel Sheet Roll Forming Machine. The state-of-the-art machinery is set to revolutionize the construction industry by streamlining the process of producing colored metal steel sheets. With unrivaled efficiency and precision, this innovative machine promises to transform the way steel sheets are manufactured and used in various construction applications.I. Background:The manufacturing industry has always been at the forefront of innovation, continuously striving to enhance productivity while maintaining the highest quality standards. The introduction of the Colored Metal Steel Sheet Roll Forming Machine showcases the company's commitment to revolutionize the construction sector by providing advanced solutions to meet market demands.II. Features and Functionality:The Colored Metal Steel Sheet Roll Forming Machine incorporates state-of-the-art technology, boasting a wide range of features that set it apart from conventional machinery. It has been meticulously designed and engineered to offer maximum efficiency, ease of use, and versatility to meet the changing needs of the construction industry.1. Advanced Roll Forming System:The machine employs an advanced roll forming system capable of producing a vast range of colored metal steel sheets. The system ensures high precision and accuracy during the roll forming process, resulting in sheets with consistent shape, dimensions, and surface finish.2. Customizable Profiles:By leveraging the machine's flexible capabilities, users can effortlessly customize various steel sheet profiles to cater to diverse construction requirements. These profiles can be easily adjusted, allowing for quick adaptation to different project specifications.3. Integrated Color Coating System:The Colored Metal Steel Sheet Roll Forming Machine is equipped with a sophisticated color coating system that ensures seamless application of vibrant colors onto the steel sheets. This feature enables the creation of visually appealing and long-lasting colored metal sheets, adding aesthetic value to any construction project.4. Energy-Efficient Operation:The machine incorporates an energy-efficient system that minimizes power consumption while maximizing productivity. This eco-friendly feature not only reduces operating costs but also contributes to a sustainable manufacturing process.III. Benefits and Market Impact:The introduction of the Colored Metal Steel Sheet Roll Forming Machine significantly enhances the overall efficiency and quality of steel sheet production, offering a wide array of benefits to construction professionals and manufacturers alike.1. Improved Productivity:With its advanced technology and streamlined functions, the machine enables faster production cycles, ensuring higher output and reduced lead times. This allows manufacturers to meet escalating market demands while maintaining stringent quality control.2. Cost Savings:The machine's energy-efficient operation and reduced material waste result in significant cost savings for manufacturers. Moreover, the customizable profiles cater to specific project requirements, minimizing material wastage and further optimizing resource utilization.3. Enhanced Durability:The use of high-quality colored metal steel sheets produced by this machine ensures enhanced durability and longevity of constructed structures. These steel sheets are resistant to corrosion, UV radiation, and extreme weather conditions, ensuring long-lasting performance and minimal maintenance costs.4. Aesthetically Pleasing:The availability of vibrant and customizable colors through the color coating system allows architects and designers to unleash their creativity. This feature paves the way for the development of visually appealing buildings and structures, adding value through aesthetic appeal.IV. Conclusion:The introduction of the Colored Metal Steel Sheet Roll Forming Machine signifies a groundbreaking leap forward in the construction industry. With its advanced technology and unmatched efficiency, this innovative machine promises to revolutionize the manufacturing of colored metal steel sheets, providing construction professionals with high-quality, customizable, and visually appealing solutions. As this technology gains traction, it is expected to reshape the construction landscape by empowering architects, engineers, and contractors to construct remarkable buildings that stand the test of time.

Steel Sheet Decking Floor Production Roll Forming Line: A Complete Guide

Metal Steel Sheet Decking Floor Production Roll Forming Line Launches by Leading Manufacturing Company[Company Name], a leading manufacturer in the industry, has announced the launch of its new Metal Steel Sheet Decking Floor Production Roll Forming Line. This innovative product is designed to meet the increasing demand for high-quality, durable and efficient metal decking floor production equipment.The Metal Steel Sheet Decking Floor Production Roll Forming Line is equipped with advanced technology and precision engineering, making it one of the most reliable and efficient solutions available in the market. The production line is capable of producing a wide range of metal decking floor profiles, catering to the diverse needs of the construction and building industry.With a focus on providing cost-effective and sustainable solutions, [Company Name] has invested extensive resources in the research and development of the Metal Steel Sheet Decking Floor Production Roll Forming Line. The company’s dedication to innovation and quality is evident in the performance and reliability of this new product, setting a new standard for metal decking floor production equipment.The Metal Steel Sheet Decking Floor Production Roll Forming Line is designed for ease of use and maintenance, allowing manufacturers to achieve higher productivity and efficiency in their operations. The production line is equipped with state-of-the-art control systems and automation technology, ensuring seamless operation and consistent output.In addition to its technological advancements, the Metal Steel Sheet Decking Floor Production Roll Forming Line also meets the industry’s safety and quality standards. The production line is engineered to deliver precise and accurate results, minimizing material waste and ensuring the highest level of product integrity.As a leading manufacturer with a strong commitment to customer satisfaction, [Company Name] provides comprehensive support and after-sales service for the Metal Steel Sheet Decking Floor Production Roll Forming Line. The company’s team of skilled engineers and technicians are dedicated to assisting customers with installation, training, and ongoing technical support, ensuring that the production line operates at its optimal performance.With the launch of the Metal Steel Sheet Decking Floor Production Roll Forming Line, [Company Name] further solidifies its position as a reliable and trusted partner for manufacturers in the construction and building industry. The company’s extensive experience and expertise in metal forming technology have made it a preferred choice for businesses looking for high-performance production equipment.[Company Name] is committed to driving innovation and delivering value to its customers through the continuous development of advanced manufacturing solutions. The Metal Steel Sheet Decking Floor Production Roll Forming Line is a testament to the company’s unwavering dedication to quality, efficiency and customer satisfaction.For more information about the Metal Steel Sheet Decking Floor Production Roll Forming Line and other products and services offered by [Company Name], please visit their website or contact their sales team directly.

Get a Glazed Tile Roof Panel Corrugation Machine for Durable and Attractive Rooftops

Glazed Tile Roof Panel Corrugation Machine revolutionizes the roofing industryThe roofing industry has undergone a significant transformation with advanced technology and efficient tools that have made the process faster, safer, and more durable. The Glazed Tile Roof Panel Corrugation Machine has emerged as one of the top tools in the roofing industry that has revolutionized the art of roofing. The machine has revamped the traditional way of roofing by transforming the way roofing panels are made, cut, and shaped.The Glazed Tile Roof Panel Corrugation Machine is the steel roll forming machine that shapes panels into various forms and sizes. The machine is designed to produce glazed tile panels with diverse profiles. The glazed tile panels add elegance to the building's structure and are durable, long-lasting, and attractive. The machine is designed to maintain the shape of the panel by forming it into a corrugated sheet.This machine has many features that help operators get their jobs done quickly and efficiently. The machine is easy to operate, and it can be customized to meet the needs of any roofing business. The machine is also highly efficient and can produce up to 30 meters of tiles per minute. Additionally, the machine is highly durable and has high-quality components that ensure longer lifespan.The Glazed Tile Roof Panel Corrugation Machine is an essential tool for all types of roofing businesses. The machine can be used to make the perfect curved or arched sheet panels for both commercial and residential buildings. The machine is also designed to handle both large and small projects, making it suitable for businesses of all sizes. Its high efficiency ensures that businesses can complete projects on time.The high-quality components of the Glazed Tile Roof Panel Corrugation Machine guarantee its longevity. The machine is made of materials that are resistant to rust and damage, ensuring a longer lifespan. Additionally, the machine is designed to be easy to maintain, reducing downtime and increasing productivity.The Glazed Tile Roof Panel Corrugation Machine is an excellent investment for any roofing business. Its high efficiency, durability, and low maintenance cost make it a cost-effective solution for any roofing project. The machine is designed to produce high-quality products, ensuring customer satisfaction and loyalty.About the CompanyOur company has been in the roofing industry for over a decade, and we understand the needs of roofing businesses. We have invested heavily in advanced technology and equipment to offer our customers the best products and services. We specialize in producing high-quality roofing sheet panels that are durable, attractive, and long-lasting. Our team of experts is highly skilled and experienced in the roofing industry, ensuring that we exceed our customer's expectations.Our primary focus is customer satisfaction, and we strive to meet our customer's needs by providing them with top-notch products, timely delivery, and excellent customer support. We take pride in our work and ensure that we go above and beyond to exceed our customer's expectations.ConclusionThe Glazed Tile Roof Panel Corrugation Machine is a game-changer in the roofing industry. It has revolutionized the traditional way of roofing and made the process faster, safer, and more durable. The machine's high efficiency, durability, and low maintenance cost make it an excellent investment for any roofing business. As a company, we understand the roofing industry's needs and have invested heavily in advanced technology to offer our customers the best products and services. Our team of experts is highly skilled and experienced, ensuring that we exceed our customer's expectations.

Top Roof Sheet Rolling Machine for Efficient Metal Roofing

Roof Sheet Rolling Machine Revolutionizing the Construction IndustryThe construction industry is constantly evolving and advancing, and one of the latest innovations making waves in the market is the Roof Sheet Rolling Machine. This state-of-the-art machine has been hailed as a game-changer in the construction sector, offering a faster, more efficient, and cost-effective solution for producing high-quality and durable roofing sheets.The Roof Sheet Rolling Machine is designed to roll and shape metal sheets into various roofing profiles, such as corrugated, trapezoidal, and standing seam profiles. It is capable of processing a wide range of materials, including steel, aluminum, and copper, making it a versatile and adaptable tool for construction projects of all sizes and scales.One of the key features of the Roof Sheet Rolling Machine is its speed and efficiency. Traditional methods of producing roofing sheets involved manual labor and were time-consuming, labor-intensive, and often prone to human error. With the Roof Sheet Rolling Machine, these inefficiencies are a thing of the past. The machine is capable of rolling out large quantities of roofing sheets in a fraction of the time it would take using traditional methods, significantly increasing productivity and reducing labor costs.In addition to its speed and efficiency, the Roof Sheet Rolling Machine also offers superior precision and quality. The machine is equipped with advanced technology and precision engineering, ensuring that every roofing sheet produced is of the highest standard. This level of precision is essential in the construction industry, where the quality and durability of roofing materials are paramount.Furthermore, the Roof Sheet Rolling Machine is designed with user-friendly features that make it easy to operate and maintain. Its intuitive controls and programmable settings allow for seamless operation, while its robust construction and durable components ensure long-term reliability and minimal downtime.One of the leading manufacturers of Roof Sheet Rolling Machines is {}, a renowned company with a long-standing reputation for producing high-quality and innovative construction machinery.{} has been at the forefront of the construction machinery industry for over two decades, and their Roof Sheet Rolling Machines have become a staple in the market. The company’s commitment to research and development, coupled with their dedication to providing cutting-edge solutions for the construction sector, has solidified their position as a trusted and reliable supplier of Roof Sheet Rolling Machines.In addition to their superior product offerings, {} is also known for their exceptional customer service and support. With a global network of service centers and knowledgeable technical staff, the company is committed to ensuring that their customers receive the highest level of support and assistance throughout the entire lifecycle of their Roof Sheet Rolling Machines.The Roof Sheet Rolling Machine is quickly becoming a must-have tool for construction companies and roofing contractors around the world. Its ability to streamline the production process, improve the quality of roofing materials, and ultimately reduce costs has made it an invaluable asset in the construction industry.As the demand for efficient and high-quality roofing solutions continues to grow, the Roof Sheet Rolling Machine is positioned to play a significant role in shaping the future of the construction industry. With its advanced technology, precision engineering, and user-friendly design, it is revolutionizing the way roofing sheets are produced and is poised to become an indispensable tool for construction projects of all kinds.

6 Tips for Choosing the Right Sheet Metal Form Roller for Your Project

Sheet metal forming is an essential process in the manufacturing industry, and the technology used in this field continues to advance rapidly. One of the key components of sheet metal forming is the form roller, which is utilized to shape and bend metal sheets into various forms. In this regard, {Company Name} is a leading manufacturer of form rollers, and their latest innovation in this field is set to revolutionize the sheet metal forming industry. With a strong reputation for high-quality products and cutting-edge technology, {Company Name} has been at the forefront of the industry for over a decade. The newest form roller from {Company Name} is designed to offer increased precision, efficiency, and versatility in sheet metal forming processes. Utilizing advanced materials and innovative engineering, this form roller is capable of delivering superior performance and durability, making it an indispensable tool for manufacturers in a wide range of industries.One of the key features of this new form roller is its enhanced precision. With state-of-the-art technology and a meticulous attention to detail in the manufacturing process, {Company Name} has ensured that this form roller can achieve the most intricate and exacting specifications. This level of precision is crucial in sheet metal forming, where even the smallest deviation can result in a defective final product.Moreover, the new form roller is also designed to be highly efficient. By reducing the time and energy required for sheet metal forming, manufacturers can improve their overall productivity and reduce production costs. This is particularly important in today's competitive market, where efficiency and cost-effectiveness are key factors in maintaining a competitive edge.Another standout feature of the new form roller is its versatility. It is capable of handling a wide variety of materials, including steel, aluminum, and other metals commonly used in the manufacturing industry. This versatility makes the form roller from {Company Name} a valuable investment for manufacturers dealing with diverse materials and production requirements.In addition to its impressive technical specifications, the new form roller from {Company Name} also boasts a user-friendly design. With intuitive controls and a focus on safety, this form roller is easy to operate and maintain, allowing manufacturers to streamline their production processes without compromising on worker safety or well-being.The release of this innovative form roller underscores {Company Name}'s commitment to driving advancements in the sheet metal forming industry. By continually pushing the boundaries of what is possible in this field, {Company Name} has solidified its reputation as a trusted and forward-thinking partner for manufacturers around the world.In conclusion, the new form roller from {Company Name} represents a significant leap forward in the sheet metal forming industry. With its emphasis on precision, efficiency, versatility, and user-friendliness, this form roller is poised to set new standards for quality and performance in sheet metal forming processes. As manufacturers continue to seek ways to improve their production capabilities, {Company Name} remains a steadfast ally, providing them with the tools they need to thrive in a constantly evolving industry.

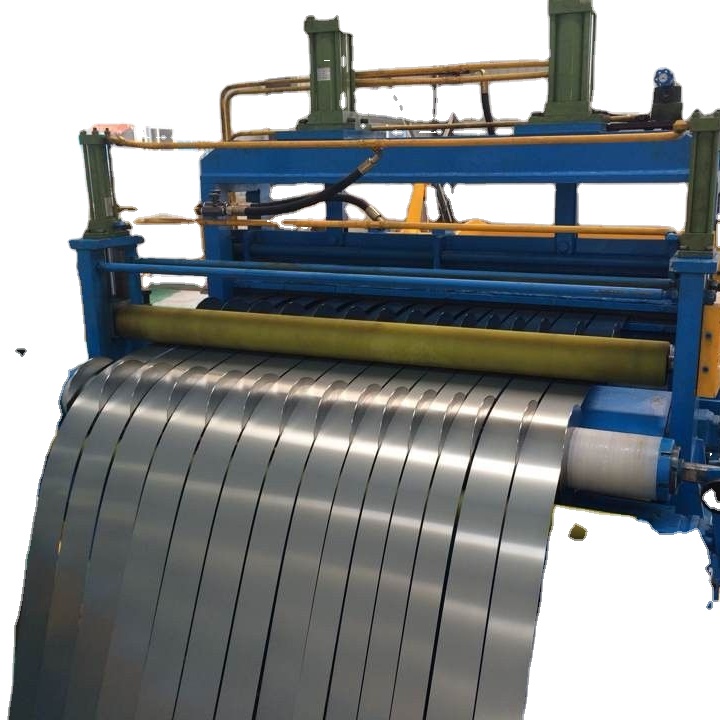

The Basics of Slitting Process in Sheet Metal: Everything You Need to Know

The slitting process in sheet metal is a crucial step in the manufacturing of various products and components. This process involves taking a large roll of sheet metal and cutting it into smaller, more manageable strips. These strips are then further processed to create a wide range of finished products, from automotive parts to household appliances to construction materials.One company at the forefront of the sheet metal slitting process is {}. With their state-of-the-art facilities and cutting-edge technology, they are able to offer precision slitting services that meet the diverse needs of their clients. Their emphasis on quality, efficiency, and innovation has made them a leader in the industry.The slitting process begins with the uncoiling of the metal roll, which is then fed through a set of rollers that straighten the material and ensure a consistent thickness. The metal is then fed through a set of circular blades that cut it into narrower strips. These strips are then recoiled for further processing or shipped out as-is, depending on the specific requirements of the customer.One of the key advantages of the slitting process is its ability to produce consistent, high-quality strips of metal with tight tolerances. This is essential for many applications where precision is paramount. Additionally, the ability to quickly and efficiently process large rolls of metal into smaller strips allows for greater flexibility and cost savings in the manufacturing process.In addition to their cutting-edge technology, {} is known for their exceptional customer service and quick turnaround times. They work closely with their clients to understand their unique needs and specifications, and are able to tailor their slitting services to meet these requirements. This level of personalized attention has helped them forge long-lasting relationships with their customers and establish a reputation for reliability and excellence.Furthermore, {} is committed to sustainability and environmental responsibility in their operations. They have implemented various measures to minimize waste and reduce the environmental impact of their manufacturing processes. This includes the responsible disposal of scrap metal and the use of energy-efficient machinery, as well as a focus on recycling and reusing materials whenever possible.As a result of their dedication to quality, innovation, and sustainability, {} has become a trusted partner for companies across a wide range of industries. Their precision slitting services have been crucial in the production of components for automobiles, appliances, HVAC systems, and more. Their ability to deliver high-quality products in a timely manner has made them an invaluable resource for their clients, helping them stay competitive in today's ever-evolving marketplace.Looking ahead, {} is poised to continue leading the way in the sheet metal slitting industry. With ongoing investments in technology and a steadfast commitment to meeting the needs of their customers, they are well-positioned for continued growth and success. As industries continue to demand high-quality, precision-cut sheet metal, {} will be there to deliver the solutions they need.