Top Roof Tile Forming Machine - Get Quality Results Now

By:Admin

The construction industry has seen a significant advancement in technology in recent years, making building processes more efficient and sustainable. One such innovation that has been making waves in the industry is the Roof Tile Forming Machine. This state-of-the-art machine, developed by a leading machinery manufacturer, is revolutionizing the way roof tiles are produced and installed.

The Roof Tile Forming Machine is designed to automate the process of creating roofing tiles, reducing the need for manual labor and increasing production efficiency. It is capable of producing a wide range of roof tile profiles, allowing for flexibility in design and customization to suit various architectural styles and construction requirements.

One of the key advantages of this Roof Tile Forming Machine is its ability to produce high-quality roof tiles at a rapid pace. The machine is equipped with advanced technology that ensures precision and consistency in tile production, resulting in durable and aesthetically pleasing roofing solutions.

Furthermore, the Roof Tile Forming Machine is also contributing to sustainable construction practices. By utilizing this machine, manufacturers can reduce material wastage and minimize the environmental impact of traditional tile production methods. Additionally, the machine is designed to optimize energy usage, making it an environmentally responsible choice for construction companies.

The company behind this innovative Roof Tile Forming Machine has a long-standing reputation for delivering cutting-edge machinery solutions to the construction industry. With decades of experience in the manufacturing sector, the company has continually strived to push the boundaries of innovation and technology to meet the evolving needs of its customers.

In addition to its Roof Tile Forming Machine, the company offers a comprehensive range of machinery and equipment for various aspects of construction, including metal forming, roll forming, and other specialized solutions. It is committed to providing reliable, high-quality products that enable construction companies to streamline their operations and achieve superior results.

The Roof Tile Forming Machine is just one example of the company's commitment to innovation and sustainability. By investing in research and development, the company continues to introduce groundbreaking solutions that address the challenges faced by the construction industry, ultimately driving progress and efficiency in the built environment.

As the demand for sustainable and cost-effective construction solutions continues to grow, the Roof Tile Forming Machine is poised to play a pivotal role in shaping the future of the industry. Its ability to streamline tile production, reduce waste, and deliver high-quality results positions it as a valuable asset for construction companies looking to optimize their processes and enhance their overall productivity.

With its proven track record of excellence and a dedication to customer satisfaction, the company is well-positioned to meet the needs of construction companies seeking advanced machinery solutions. The Roof Tile Forming Machine, in particular, has garnered widespread attention for its potential to transform the way roof tiles are manufactured and installed, creating a ripple effect of positive impacts throughout the construction industry.

In conclusion, the Roof Tile Forming Machine represents a significant advancement in construction technology, offering a compelling solution for companies seeking to improve efficiency, sustainability, and quality in their roofing projects. With a steadfast commitment to innovation and a focus on delivering superior machinery solutions, the company behind this groundbreaking machine is poised to make a lasting impact on the construction industry for years to come.

Company News & Blog

Top Roof Sheet Rolling Machine for Efficient Metal Roofing

Roof Sheet Rolling Machine Revolutionizing the Construction IndustryThe construction industry is constantly evolving and advancing, and one of the latest innovations making waves in the market is the Roof Sheet Rolling Machine. This state-of-the-art machine has been hailed as a game-changer in the construction sector, offering a faster, more efficient, and cost-effective solution for producing high-quality and durable roofing sheets.The Roof Sheet Rolling Machine is designed to roll and shape metal sheets into various roofing profiles, such as corrugated, trapezoidal, and standing seam profiles. It is capable of processing a wide range of materials, including steel, aluminum, and copper, making it a versatile and adaptable tool for construction projects of all sizes and scales.One of the key features of the Roof Sheet Rolling Machine is its speed and efficiency. Traditional methods of producing roofing sheets involved manual labor and were time-consuming, labor-intensive, and often prone to human error. With the Roof Sheet Rolling Machine, these inefficiencies are a thing of the past. The machine is capable of rolling out large quantities of roofing sheets in a fraction of the time it would take using traditional methods, significantly increasing productivity and reducing labor costs.In addition to its speed and efficiency, the Roof Sheet Rolling Machine also offers superior precision and quality. The machine is equipped with advanced technology and precision engineering, ensuring that every roofing sheet produced is of the highest standard. This level of precision is essential in the construction industry, where the quality and durability of roofing materials are paramount.Furthermore, the Roof Sheet Rolling Machine is designed with user-friendly features that make it easy to operate and maintain. Its intuitive controls and programmable settings allow for seamless operation, while its robust construction and durable components ensure long-term reliability and minimal downtime.One of the leading manufacturers of Roof Sheet Rolling Machines is {}, a renowned company with a long-standing reputation for producing high-quality and innovative construction machinery.{} has been at the forefront of the construction machinery industry for over two decades, and their Roof Sheet Rolling Machines have become a staple in the market. The company’s commitment to research and development, coupled with their dedication to providing cutting-edge solutions for the construction sector, has solidified their position as a trusted and reliable supplier of Roof Sheet Rolling Machines.In addition to their superior product offerings, {} is also known for their exceptional customer service and support. With a global network of service centers and knowledgeable technical staff, the company is committed to ensuring that their customers receive the highest level of support and assistance throughout the entire lifecycle of their Roof Sheet Rolling Machines.The Roof Sheet Rolling Machine is quickly becoming a must-have tool for construction companies and roofing contractors around the world. Its ability to streamline the production process, improve the quality of roofing materials, and ultimately reduce costs has made it an invaluable asset in the construction industry.As the demand for efficient and high-quality roofing solutions continues to grow, the Roof Sheet Rolling Machine is positioned to play a significant role in shaping the future of the construction industry. With its advanced technology, precision engineering, and user-friendly design, it is revolutionizing the way roofing sheets are produced and is poised to become an indispensable tool for construction projects of all kinds.

Galvanized Roofing Sheet Making Machine for Color Steel Roof Sheets

Color Steel Roof Sheet Making Galvanized Roofing Sheet Press Machine Revolutionizes Roofing IndustryIn a breakthrough development for the roofing industry, a cutting-edge Color Steel Roof Sheet Making Galvanized Roofing Sheet Press Machine has been launched. This innovative machine is set to revolutionize the manufacture of roofing sheets, offering enhanced efficiency, reliability, and quality.Designed and manufactured by an industry-leading company with a proven track record of delivering high-quality machinery for the construction sector, this advanced press machine is a game-changer for roofing sheet production. By leveraging state-of-the-art technology and precision engineering, the machine is capable of producing galvanized roofing sheets with impeccable precision and consistency.The company behind this groundbreaking machine has established itself as a trailblazer in the field of metal fabrication equipment. With a commitment to innovation and excellence, the company has earned a reputation for delivering cutting-edge solutions that meet the evolving needs of the construction industry.The Color Steel Roof Sheet Making Galvanized Roofing Sheet Press Machine is a testament to the company's dedication to pushing the boundaries of what is possible in the realm of construction machinery. By integrating advanced automation and intelligent control systems, the machine streamlines the manufacturing process, allowing for higher production volumes while maintaining the highest standards of quality.One of the key features of the new press machine is its ability to produce color steel roof sheets with galvanized coating, ensuring exceptional durability and weather resistance. This is a critical advantage for roofing materials, as they must withstand the elements and provide long-lasting protection for buildings.Moreover, the machine's efficient use of raw materials and energy underscores its sustainability credentials, aligning with the growing emphasis on environmentally-friendly practices in the construction sector. By optimizing resource utilization and minimizing waste, the machine helps reduce the environmental footprint of roofing sheet production.The introduction of the Color Steel Roof Sheet Making Galvanized Roofing Sheet Press Machine is poised to bring about a paradigm shift in the roofing industry. With its unmatched performance and reliability, the machine offers a competitive edge to manufacturers seeking to elevate the quality of their products and optimize their operations.In addition to its technical prowess, the machine reflects the company's commitment to providing comprehensive support to its customers. From installation and training to ongoing maintenance and technical assistance, the company ensures that its clients can harness the full potential of the press machine, maximizing their return on investment.The unveiling of the Color Steel Roof Sheet Making Galvanized Roofing Sheet Press Machine represents a significant milestone for the company and the roofing industry at large. It underscores the company's standing as an industry leader and sets a new benchmark for excellence in roofing sheet manufacturing.Looking ahead, the company remains focused on advancing its mission to drive innovation and progress in the construction equipment sector. With a robust pipeline of cutting-edge solutions in development, the company is poised to continue reshaping the industry and empowering its customers to thrive in a rapidly evolving market.In conclusion, the debut of the Color Steel Roof Sheet Making Galvanized Roofing Sheet Press Machine marks a watershed moment in the roofing industry. By harnessing the latest technological advancements and engineering ingenuity, the machine sets a new standard for efficiency, quality, and sustainability in roofing sheet production. As the industry embraces this transformative innovation, manufacturers can look forward to realizing new levels of productivity and performance in their operations.

High-Quality Sheet Corrugation Machine: Everything You Need to Know

Sheet Corrugation Machine Revolutionizes Packaging IndustryIn today's fast-paced world, the demands for efficient and cost-effective packaging solutions are increasing at an unprecedented rate. With the rise of e-commerce and the need for sustainable packaging materials, companies are constantly seeking innovative technologies to streamline their packaging processes. This is where the sheet corrugation machine comes into play, revolutionizing the packaging industry with its advanced features and capabilities.The sheet corrugation machine, offered by a leading packaging machinery manufacturer, is a game-changer in the industry. With a focus on providing high-quality and cost-effective solutions for businesses of all sizes, the company has established itself as an industry leader in the manufacturing of corrugated packaging machinery. Their sheet corrugation machine is a testament to their commitment to innovation and excellence in the field of packaging.One of the key advantages of the sheet corrugation machine is its ability to produce high-quality corrugated sheets with precision and efficiency. This machine is designed to handle various types of corrugated board materials, offering flexibility and versatility to meet the diverse needs of packaging applications. Whether it's for custom packaging designs or standard box manufacturing, the sheet corrugation machine delivers consistent and reliable results, making it an indispensable tool for manufacturers.Furthermore, the sheet corrugation machine is equipped with advanced features that enhance productivity and reduce downtime. Its user-friendly interface and intuitive controls make it easy to operate, allowing for seamless integration into existing packaging processes. Additionally, the machine's automated functions and real-time monitoring capabilities ensure optimal performance, leading to increased production output and cost savings for businesses.Another notable feature of the sheet corrugation machine is its focus on sustainability. As the packaging industry continues to prioritize environmentally-friendly solutions, this machine is designed with eco-conscious features that minimize material waste and energy consumption. By producing high-quality corrugated sheets with minimal impact on the environment, the machine aligns with the growing demand for sustainable packaging practices.In addition to its technical capabilities, the company behind the sheet corrugation machine prides itself on providing excellent customer support and after-sales service. With a team of experienced professionals, they offer comprehensive training, maintenance, and troubleshooting assistance to ensure that their customers maximize the potential of the machine. This commitment to customer satisfaction further solidifies the company's reputation as a trusted partner in the packaging industry.The impact of the sheet corrugation machine in the packaging industry is undeniable. Its ability to deliver high-quality corrugated sheets, enhance productivity, promote sustainability, and provide exceptional customer support makes it a valuable asset for businesses looking to stay ahead in the competitive market. As the demand for efficient and cost-effective packaging solutions continues to grow, the sheet corrugation machine proves to be an essential investment for companies seeking to innovate their packaging processes.In conclusion, the sheet corrugation machine offered by the company is a game-changer in the packaging industry, revolutionizing the way businesses approach their packaging needs. With its advanced features, focus on sustainability, and commitment to customer support, this machine sets a new standard for corrugated packaging machinery. As businesses strive to keep up with the evolving demands of the market, the sheet corrugation machine proves to be a valuable asset for achieving efficiency, cost savings, and high-quality packaging solutions.

High-Quality Roof Panel Forming Machine for Efficient Roofing Production

In recent years, the demand for sustainable and energy-efficient housing solutions has been on the rise, leading to a growing interest in innovative construction technologies. One such technological advancement is the Roof Panel Forming Machine, a cutting-edge equipment that has the capability to revolutionize the way roofing solutions are manufactured and installed.The Roof Panel Forming Machine, offered by a leading company in the construction industry, utilizes state-of-the-art technology to produce high-quality roofing panels with precision and efficiency. With its advanced design and automated operation, this machine has the capability to significantly reduce the time and labor required to manufacture roofing panels, while also ensuring consistent quality and precision in every panel produced.The company behind the Roof Panel Forming Machine is a renowned industry leader with a strong focus on innovation and technological advancements. With years of experience and expertise in the construction sector, the company has established itself as a trusted provider of cutting-edge solutions for the building and construction industry.The Roof Panel Forming Machine is just one of the many innovative products offered by the company, which prides itself on its commitment to delivering high-quality, reliable, and efficient solutions to meet the evolving needs of the construction industry. In addition to its advanced technology and engineering expertise, the company also places a strong emphasis on sustainability, ensuring that its products are designed to minimize environmental impact and contribute to the development of more eco-friendly construction practices.With its dedicated team of professionals and its state-of-the-art manufacturing facilities, the company is well-equipped to meet the growing demand for advanced construction technologies, including the Roof Panel Forming Machine. The company's commitment to research and development, coupled with its focus on customer satisfaction, has enabled it to establish a strong presence in the global construction market, earning the trust and confidence of industry professionals and clients alike.In addition to its innovative products and cutting-edge technologies, the company also offers comprehensive support and after-sales services, ensuring that its clients receive the necessary assistance and guidance to maximize the potential of their investment in the Roof Panel Forming Machine. From installation and training to technical support and maintenance, the company is dedicated to ensuring the success of its clients and the seamless integration of its advanced construction solutions into their operations.As the demand for sustainable and energy-efficient construction solutions continues to grow, the Roof Panel Forming Machine offered by the company represents a significant leap forward in the construction industry. With its capacity to streamline the manufacturing process, enhance the quality of roofing solutions, and contribute to more sustainable construction practices, this innovative machine is poised to make a lasting impact on the industry.In conclusion, the Roof Panel Forming Machine, offered by the leading company in the construction industry, is a testament to the potential of advanced technologies to revolutionize the way we build and develop the infrastructure for the future. With its commitment to innovation, quality, and sustainability, the company is well-positioned to lead the way in delivering cutting-edge solutions that address the evolving needs of the construction sector and contribute to the development of more efficient, sustainable, and resilient building practices.

Efficient Horizontal Barrel Vault Panel Cutting Machine for Improved Productivity

Horizontal Barrel Vault Panel Cutting Machine Revolutionizes the IndustryThe manufacturing industry is constantly evolving and adapting to new technologies. In recent years, the demand for precision and efficiency in panel cutting has grown significantly, prompting companies to invest in advanced machinery to meet these requirements. One such innovative solution is the Horizontal Barrel Vault Panel Cutting Machine, a cutting-edge tool that is revolutionizing the industry.This groundbreaking machine, produced by a leading global manufacturing company, is designed to meet the specific needs of panel cutting for a wide range of industries, including construction, automotive, aerospace, and more. With its advanced technology and versatile capabilities, the Horizontal Barrel Vault Panel Cutting Machine has quickly become the go-to solution for businesses looking to enhance their cutting operations.One of the key features of the Horizontal Barrel Vault Panel Cutting Machine is its precision cutting capabilities. The machine is equipped with state-of-the-art technology that allows for extremely accurate and consistent cuts, ensuring high-quality results every time. This level of precision is crucial for industries that require intricate and complex panel designs, such as the aerospace and automotive sectors.In addition to its precision cutting abilities, the Horizontal Barrel Vault Panel Cutting Machine also offers exceptional speed and efficiency. Its advanced automation and cutting processes enable rapid production without compromising on quality. This not only saves businesses valuable time and resources but also allows for increased output and productivity.Furthermore, the versatility of the Horizontal Barrel Vault Panel Cutting Machine makes it an invaluable asset for a wide range of applications. Whether it's cutting materials such as metal, plastic, or composite panels, this machine can easily accommodate various materials and thicknesses, making it a versatile and adaptable solution for different manufacturing needs.The company behind this cutting-edge technology has a long-standing reputation for delivering high-quality manufacturing machinery. With a strong focus on innovation and continuous improvement, the company is committed to providing reliable and efficient solutions that meet the evolving needs of the industry.The Horizontal Barrel Vault Panel Cutting Machine is just one example of the company's dedication to developing cutting-edge technology that pushes the boundaries of what is possible in manufacturing. By combining advanced engineering with practical solutions, the company has established itself as a leader in the industry, with a track record of delivering innovative and reliable products.In addition to its cutting-edge machinery, the company also offers comprehensive support and services to ensure that its customers can maximize the potential of their equipment. From installation and training to maintenance and technical support, the company is dedicated to providing ongoing value to its customers, helping them achieve their production goals and maintain a competitive edge in the market.The impact of the Horizontal Barrel Vault Panel Cutting Machine on the manufacturing industry cannot be understated. Its precision, speed, and versatility have set a new standard for panel cutting, raising the bar for efficiency and quality in manufacturing operations. As businesses continue to embrace advanced technology and automation, the demand for innovative solutions like this machine is only expected to grow.In conclusion, the Horizontal Barrel Vault Panel Cutting Machine represents a significant advancement in the manufacturing industry, offering game-changing capabilities that are redefining the way panels are cut. With its precision, speed, and versatility, this cutting-edge machine is empowering businesses to elevate their manufacturing processes and achieve new levels of efficiency and quality. As the industry continues to evolve, the impact of this revolutionary technology is sure to be felt for years to come.

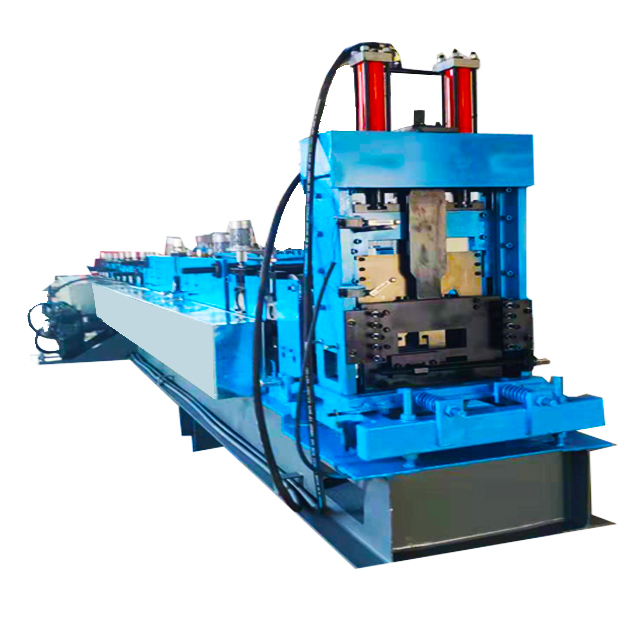

High-Quality C Purlin Roll Forming Machine: A Complete Guide

The Manual C Purlin Roll Forming Machine is a game changer in the metalworking industry. This innovative machine is designed to produce high-quality C-shaped steel purlins with ease and efficiency. With its user-friendly manual operation, it is suitable for small to medium-sized enterprises and individuals looking to produce C purlins for construction projects.Company Introduction:Established in 2005, our company has been a pioneer in the field of metalworking machinery. Our dedication to continuous innovation and customer satisfaction has propelled us to become a leading manufacturer of roll forming machines. With a strong focus on research and development, we have consistently introduced cutting-edge technologies to the market, earning us a reputation for excellence and reliability.News Content:The Manual C Purlin Roll Forming Machine is a testament to our commitment to providing advanced solutions for our customers. This state-of-the-art machine is the ideal choice for businesses or individuals seeking to produce C purlins with precision and efficiency. With its manual operation, it offers an intuitive and user-friendly experience, making it accessible to operators of all skill levels.What sets this machine apart is its ability to produce high-quality C purlins with consistency. The precision engineering of the roll forming process ensures that each purlin meets the required specifications, whether it's for residential, commercial, or industrial construction projects. This level of accuracy is essential for ensuring the structural integrity and stability of buildings, making it a valuable asset for any metalworking operation.In addition to its performance, the Manual C Purlin Roll Forming Machine is designed with practicality in mind. Its compact size and efficient operation make it a space-saving and cost-effective solution for small to medium-sized enterprises. Furthermore, its manual operation eliminates the need for complex programming or extensive training, allowing operators to quickly familiarize themselves with the machine and start producing C purlins without unnecessary delays.The versatility of the Manual C Purlin Roll Forming Machine extends to its ability to accommodate a wide range of material thicknesses and widths, offering operators the flexibility to meet various project requirements. This adaptability is essential in the ever-changing construction industry, where diverse purlin specifications are often necessary to meet specific building designs and structural demands.As a testament to our ongoing commitment to customer satisfaction, the Manual C Purlin Roll Forming Machine is backed by our comprehensive technical support and training services. Our team of experts is readily available to provide guidance on machine operation, maintenance, and troubleshooting, ensuring that our customers can maximize the machine's capabilities and achieve optimal results.In conclusion, the Manual C Purlin Roll Forming Machine represents a significant advancement in the field of metalworking machinery. Its combination of high-performance capabilities, user-friendly operation, and versatility makes it a valuable addition to any metalworking operation. As we continue to uphold our tradition of innovation and excellence, we are confident that this machine will deliver exceptional value to our customers and contribute to the success of their construction projects.

High-efficiency Aluminum Extrusion Punching Machine for Precision Metal Fabrication

Aluminum extrusion punching machines have revolutionized the manufacturing industry by offering a fast and efficient way to create intricate and precise aluminum products. These machines are equipped with advanced technology and precision engineering, allowing manufacturers to produce high-quality aluminum extrusions for a wide range of applications.One of the leading manufacturers of aluminum extrusion punching machines is {Company Name}. With a strong focus on innovation and quality, {Company Name} has established itself as a trusted name in the industry. The company is known for its cutting-edge technology and advanced design, which has set new standards in the aluminum extrusion industry.{Company Name} offers a wide range of aluminum extrusion punching machines to cater to the diverse needs of its customers. Whether it's for small-scale production or large-scale manufacturing, the company's machines are designed to deliver exceptional performance and efficiency. With a strong emphasis on precision and accuracy, {Company Name} has become a preferred choice for manufacturers looking to optimize their production processes.In addition to its cutting-edge technology, {Company Name} is also committed to providing excellent customer service and support. The company has a team of highly skilled engineers and technicians who are dedicated to delivering top-notch solutions for its customers. From installation and training to maintenance and repairs, {Company Name} ensures that its customers are well-supported throughout the lifespan of their machines.Furthermore, {Company Name} places a strong emphasis on research and development, constantly striving to innovate and improve its products. This commitment to innovation has allowed the company to stay ahead of the curve and continue to meet the evolving needs of the industry. {Company Name} is constantly investing in new technologies and processes to ensure that its machines remain at the forefront of the aluminum extrusion industry.With a global presence, {Company Name} has been able to establish strong partnerships with manufacturers around the world. The company's machines are widely used in various industries, including automotive, construction, electronics, and more. {Company Name} takes pride in its ability to support a diverse range of manufacturers, helping them achieve their production goals with its advanced aluminum extrusion punching machines.As the demand for aluminum extrusions continues to grow, {Company Name} remains committed to providing innovative and reliable solutions to its customers. With a focus on quality, precision, and customer satisfaction, the company is well-positioned to lead the way in the aluminum extrusion industry. Its dedication to excellence and continuous improvement has solidified {Company Name} as a trusted and respected name in the manufacturing sector.In conclusion, the aluminum extrusion punching machines offered by {Company Name} are a game-changer for manufacturers looking to streamline their production processes. With a strong focus on innovation, quality, and customer support, {Company Name} has established itself as a leader in the industry. The company's commitment to excellence and constant improvement sets it apart as a preferred choice for manufacturers around the world.

Highly efficient metal wall panel machine for producing precision panels

Metal Wall Panel Machine Leads the Industry with Innovative Technology{Company Name}, a leading manufacturer of metal forming machinery, has recently unveiled its latest innovation in the field of metal wall panel production - the new {Machine Model}.With years of experience in the industry, {Company Name} has been at the forefront of developing high-quality, advanced machinery for the metal forming industry. The {Machine Model} is the latest addition to their wide range of metal forming equipment, and it promises to revolutionize the production of metal wall panels.The {Machine Model} is equipped with state-of-the-art technology that allows for precision forming and shaping of metal panels. Its advanced features include a high-speed servo drive system, which ensures precise and smooth operation, resulting in consistently high-quality panels. The machine is also designed to accommodate a wide range of panel sizes and shapes, making it suitable for a variety of applications in the construction and architectural industries.One of the key advantages of the {Machine Model} is its versatility. It is capable of producing a variety of panel profiles, including flat, ribbed, and corrugated panels, as well as custom designs to meet the specific requirements of customers. This flexibility makes the {Machine Model} an ideal choice for manufacturers looking to diversify their product offerings and cater to a wider range of market demands.Moreover, the {Machine Model} is designed with efficiency in mind. It features a user-friendly interface and intuitive controls, making it easy to operate and requiring minimal training for operators. Additionally, the machine's quick changeover capabilities and automated tooling adjustments contribute to increased productivity and reduced downtime, leading to cost savings for manufacturers.In terms of durability and reliability, the {Machine Model} is built to last. Its robust construction and high-quality components ensure long-term performance and minimal maintenance requirements, allowing manufacturers to focus on their production processes without worrying about frequent equipment breakdowns or repairs.The introduction of the {Machine Model} has set a new standard in the metal forming industry. It represents a significant leap forward in technology, offering manufacturers the opportunity to enhance their production capabilities and deliver superior quality products to their customers.{Company Name} has a long-standing reputation for delivering innovative solutions and best-in-class machinery to the metal forming industry, and the {Machine Model} is a testament to their commitment to excellence. With its cutting-edge technology and advanced features, the {Machine Model} is poised to lead the industry and set new benchmarks for metal wall panel production.As the global demand for high-quality, custom metal wall panels continues to grow, the {Machine Model} is set to play a pivotal role in meeting these needs and supporting manufacturers in their quest for innovation and competitiveness. Its ability to streamline production processes, increase efficiency, and deliver outstanding results will undoubtedly make it a sought-after choice for metal forming companies around the world.In conclusion, the {Machine Model} from {Company Name} is a game-changer in the metal forming industry. Its groundbreaking technology, unmatched versatility, and superior performance make it a must-have for manufacturers looking to stay ahead in a competitive market. As the industry evolves, {Company Name} remains at the forefront, driving innovation and empowering manufacturers to excel in their metal forming endeavors.

High-Quality C-Section Roll Forming Machine for Efficient Manufacturing

With the increasing demand for high-quality and efficient C Section Roll Forming Machines in the construction industry, {Company Name} continues to be a leading provider of innovative and reliable roll forming solutions. The company's dedication to research and development, as well as its commitment to customer satisfaction, has set it apart as a trusted partner for companies seeking top-notch roll forming equipment.The C Section Roll Forming Machine offered by {Company Name} is a state-of-the-art solution that is designed to meet the needs of modern construction projects. Featuring advanced technology and precision engineering, this machine is capable of producing high-quality C-section channels with unparalleled accuracy and efficiency. This is essential for construction companies that require consistent and reliable profiles for their building projects.One of the key features of {Company Name}'s C Section Roll Forming Machine is its versatility. This machine is capable of producing a wide range of C-section profiles, making it suitable for a variety of construction applications. Whether it's for purlins, pillars, or other structural components, this machine is designed to handle the diverse needs of the construction industry, providing companies with the flexibility they need to meet the demands of their projects.In addition to its versatility, {Company Name}'s C Section Roll Forming Machine is known for its high productivity and efficiency. With a high-speed production capability and a reliable material feeding system, this machine is able to produce C-section profiles at an impressive rate, allowing construction companies to meet tight project deadlines without compromising on quality. This level of efficiency is essential for companies that want to maximize their productivity and profitability.Another notable feature of {Company Name}'s C Section Roll Forming Machine is its user-friendly design. This machine is equipped with intuitive controls and ergonomic features that make it easy to operate and maintain. This user-friendly approach not only minimizes the learning curve for operators but also reduces the risk of errors and downtime, ultimately leading to a smoother and more efficient production process.Aside from the machine itself, {Company Name} also offers comprehensive support and services to its customers. From installation and training to maintenance and troubleshooting, the company is dedicated to ensuring that its customers are able to maximize the potential of their roll forming equipment. This level of support reflects {Company Name}'s commitment to customer satisfaction and its understanding of the importance of reliable after-sales services.{Company Name} is also known for its emphasis on quality and reliability. Each C Section Roll Forming Machine is manufactured using high-grade materials and components, ensuring durability and longevity. Rigorous quality control measures are also in place to guarantee that every machine meets the highest standards of performance and consistency. This dedication to quality is what has made {Company Name} a preferred choice for companies that value reliability and precision in their roll forming equipment.In conclusion, {Company Name}'s C Section Roll Forming Machine stands out as a leading solution for companies in the construction industry. With its advanced technology, versatility, efficiency, and user-friendly design, this machine is an essential asset for companies that are looking to elevate their roll forming capabilities. Backed by exceptional support and a reputation for quality and reliability, {Company Name} continues to be a trusted partner for companies seeking top-of-the-line roll forming solutions.

Complete Guide to Standing Seam Metal Roof Machines

[Company name], a leading manufacturer of metal roofing machines, has recently introduced its latest innovation – the Standing Seam Metal Roof Machine. This new machine is designed to offer increased efficiency and precision in the production of standing seam metal roofs, making it the perfect solution for various roofing contractors and manufacturers.The Standing Seam Metal Roof Machine is designed to produce high-quality standing seam metal roofs with ease and precision. It is equipped with state-of-the-art technology and features that make the production process faster and more efficient. The machine is capable of producing standing seam metal roofs in a variety of widths and lengths, making it suitable for a wide range of roofing projects.One of the key features of the Standing Seam Metal Roof Machine is its versatility. It is designed to be easily adjustable, allowing for quick and easy changes in panel width and length. This ensures that the machine can easily adapt to different project requirements, saving time and increasing productivity for roofing contractors and manufacturers.In addition to its versatility, the Standing Seam Metal Roof Machine is also designed with precision in mind. It is equipped with advanced controls and systems that ensure the accuracy and consistency of the finished products. This precision is essential for meeting the high standards and specifications of standing seam metal roofs, ensuring that the final product meets the requirements of the most demanding customers.Furthermore, the Standing Seam Metal Roof Machine is designed for durability and reliability. It is constructed with high-quality materials and components, making it capable of withstanding the rigors of continuous use in a production environment. This durability minimizes downtime and maintenance, ensuring that the machine can deliver consistent performance over the long term.“We are thrilled to introduce our latest innovation, the Standing Seam Metal Roof Machine,” said [Company name]'s CEO. “This machine is the result of our ongoing commitment to delivering cutting-edge solutions for the metal roofing industry. We have designed it to address the needs and challenges of our customers, providing them with a reliable and efficient solution for producing standing seam metal roofs.”[Company name] has been a trusted name in the metal roofing industry for many years. The company has a proven track record of delivering high-quality and reliable metal roofing machines that meet the needs of roofing contractors and manufacturers. The introduction of the Standing Seam Metal Roof Machine is a testament to the company's dedication to innovation and customer satisfaction.With its latest innovation, [Company name] is poised to further strengthen its position as a leading manufacturer of metal roofing machines. The Standing Seam Metal Roof Machine is set to become a game-changer in the industry, offering a level of efficiency, precision, and versatility that was previously unseen in the production of standing seam metal roofs.In conclusion, the introduction of the Standing Seam Metal Roof Machine marks a significant milestone for [Company name] and the metal roofing industry as a whole. With its advanced technology, versatility, precision, and durability, this machine is set to revolutionize the production of standing seam metal roofs, providing a reliable and efficient solution for roofing contractors and manufacturers. As [Company name] continues to push the boundaries of innovation, it is poised to further solidify its position as a trusted provider of metal roofing machines.