High-Quality Corrugated Curving Rolls for Your Packaging Needs

By:Admin

The packaging and printing industry has seen a major revolution with the introduction of advanced technologies and innovative solutions. One such groundbreaking development is the introduction of Corrugated Curving Rolls, a game-changing product that has transformed the way corrugated materials are processed and manufactured.

Corrugated Curving Rolls, produced by a leading company in the industry, have quickly gained recognition for their exceptional quality and performance. With a strong focus on innovation and customer satisfaction, the company has become a trusted partner for businesses looking to enhance their packaging and printing operations.

The Corrugated Curving Rolls are designed to provide precise and efficient curving of corrugated materials, allowing manufacturers to create custom packaging solutions with elaborate designs and shapes. This innovative technology has opened up a world of possibilities for businesses looking to differentiate their products and improve their brand recognition through unique packaging solutions.

The key features of Corrugated Curving Rolls include high precision, durability, and flexibility, making them suitable for a wide range of applications. Whether it's producing custom packaging for luxury products or creating eye-catching displays for retail environments, the versatility of these rolls has made them a popular choice among packaging and printing professionals.

One of the most impressive aspects of Corrugated Curving Rolls is their ability to streamline the production process, reducing lead times and increasing efficiency. This has a direct impact on the overall cost of production, allowing businesses to maximize their resources and improve their bottom line.

In addition to their practical benefits, Corrugated Curving Rolls also contribute to the sustainability efforts of businesses within the industry. By reducing material waste and optimizing the use of resources, these rolls help companies minimize their environmental footprint while still meeting their packaging and printing needs.

The company behind the Corrugated Curving Rolls has a rich history of delivering high-quality solutions to the packaging and printing industry. With a team of dedicated professionals and a commitment to innovation, the company has established itself as a leader in the field, continually pushing the boundaries of what is possible in packaging and printing technology.

In addition to Corrugated Curving Rolls, the company offers a comprehensive range of products and services aimed at supporting businesses in their packaging and printing endeavors. From advanced printing equipment to customized packaging solutions, the company provides a one-stop-shop for all the needs of its clients.

The success of Corrugated Curving Rolls can be attributed to the extensive research and development efforts put in by the company. By staying ahead of market trends and anticipating the evolving needs of its customers, the company has been able to develop products that are not only innovative but also highly practical and efficient.

Furthermore, the company's commitment to customer satisfaction is evident in its comprehensive support services and industry expertise. Whether it's providing technical assistance or offering tailored solutions, the company goes above and beyond to ensure that its clients have the tools and resources they need to succeed in their packaging and printing projects.

Looking ahead, the company aims to continue its track record of innovation and excellence by further expanding its product offerings and investing in cutting-edge technologies. With a focus on sustainability and cost-effectiveness, the company is poised to cement its position as a trusted partner for businesses in the packaging and printing industry.

In conclusion, Corrugated Curving Rolls have brought about a paradigm shift in the packaging and printing industry, offering businesses a new level of flexibility, efficiency, and creativity. With their ability to streamline production processes and produce custom packaging solutions, these rolls have quickly become an indispensable tool for businesses looking to stay ahead in a competitive market. As the company behind the product continues to innovate and expand its offerings, the future looks bright for the packaging and printing industry.

Company News & Blog

Durable and Stylish Horizontal Corrugated Roof Tile for Your Home

Horizontal Corrugated Roof Tile is a new innovative product that has been launched by a well-known company in the construction industry. This product is designed to provide a durable and stylish roofing solution for residential and commercial buildings. With its unique design and advanced technology, Horizontal Corrugated Roof Tile is set to revolutionize the roofing industry and provide customers with a high-quality, long-lasting solution for their roofing needs.The company producing Horizontal Corrugated Roof Tile has been a leader in the construction industry for many years. They are known for their commitment to quality and innovation, and this new product is a testament to their dedication to providing customers with the best possible solutions for their building needs. With a strong focus on research and development, the company has been able to create a product that meets the highest standards of quality and performance.Horizontal Corrugated Roof Tile is designed to withstand the elements and provide superior protection for buildings. The unique corrugated design of the tiles allows for maximum strength and durability, while also creating a sleek and modern look for any building. The tiles are made from high-quality materials that are designed to last for many years, making them an excellent investment for any property owner.In addition to its durability, Horizontal Corrugated Roof Tile is also designed to be easy to install and maintain. The tiles are lightweight and easy to handle, making the installation process quick and efficient. Once installed, the tiles require minimal maintenance, saving customers time and money in the long run. This is a key selling point for customers who want a low-maintenance roofing solution that will last for many years.Another key feature of Horizontal Corrugated Roof Tile is its versatility. The tiles are available in a wide range of colors and finishes, allowing customers to choose the perfect option to complement their building design. Whether it's a residential home or a commercial building, the tiles can be customized to fit the unique style and aesthetic of any property. This versatility makes Horizontal Corrugated Roof Tile a popular choice for architects, builders, and property owners alike.The launch of Horizontal Corrugated Roof Tile has generated a lot of excitement in the construction industry. Customers are eager to take advantage of this innovative new product, and the company is already seeing a high demand for the tiles. With its combination of durability, style, and ease of installation, Horizontal Corrugated Roof Tile is poised to become a top choice for roofing solutions in the market.To meet the growing demand for Horizontal Corrugated Roof Tile, the company has ramped up production and distribution of the product. They have expanded their manufacturing facilities and have partnered with distributors and retailers to make the tiles readily available to customers. This proactive approach demonstrates the company's commitment to meeting customer needs and ensuring that Horizontal Corrugated Roof Tile is accessible to anyone looking for a reliable and attractive roofing solution.Overall, Horizontal Corrugated Roof Tile is a game-changer in the roofing industry. With its advanced technology, durability, and versatility, the tiles are set to make a lasting impact on the market and provide customers with a superior roofing solution. The company behind the product is dedicated to delivering high-quality solutions for their customers, and Horizontal Corrugated Roof Tile is a shining example of their commitment to excellence. As the product continues to gain traction in the market, it is clear that it will become a staple in the construction industry for years to come.

Roll Forming Machine for Roofing: A Complete Guide

Roofing Roll Former Revolutionizes Industry with Innovative TechnologyThe roofing industry is constantly evolving with new technologies and innovations, and one company is leading the way with its revolutionary Roofing Roll Former. With its cutting-edge technology and dedication to quality, the company has become a household name in the roofing industry.{Company Name} is a leading manufacturer of roofing equipment, specializing in roll formers that are designed to meet the specific needs of the industry. The company has been in business for over 20 years and has established a reputation for excellence and reliability. Its products are known for their durability, efficiency, and precision, making them a top choice for roofing professionals around the world.The Roofing Roll Former is the latest addition to the company's line of products, and it is already making waves in the industry. This state-of-the-art machine is designed to streamline the roofing process, making it faster, more efficient, and more cost-effective. With its advanced technology and innovative features, the Roofing Roll Former is changing the way roofing projects are completed.One of the key features of the Roofing Roll Former is its versatility. It is capable of producing a wide range of roofing profiles, allowing roofing professionals to meet the unique needs of their clients. Whether it's for residential, commercial, or industrial projects, the Roofing Roll Former can handle it all with ease. This versatility is a game-changer for the industry, providing roofing professionals with the flexibility they need to take on a variety of projects.In addition to its versatility, the Roofing Roll Former is also known for its speed and efficiency. With its high-speed production capabilities, it can significantly reduce the time it takes to complete a roofing project. This not only increases productivity but also allows roofing professionals to take on more projects, ultimately increasing their profitability. Furthermore, the precision of the Roofing Roll Former ensures that every roofing panel is manufactured to the highest standards, providing clients with a quality product that will stand the test of time.Another standout feature of the Roofing Roll Former is its user-friendly design. The machine is easy to operate and requires minimal training, making it accessible to roofing professionals of all skill levels. This accessibility is a key selling point for the Roofing Roll Former, as it allows roofing professionals to quickly integrate the machine into their workflow without the need for extensive training or retooling.The company behind the Roofing Roll Former is committed to providing top-notch customer service and support. With a team of knowledgeable and experienced professionals, they are dedicated to helping roofing professionals get the most out of their equipment. Whether it's through on-site training, technical support, or product customization, the company is there every step of the way, ensuring that its customers have everything they need to succeed.The Roofing Roll Former has already made a significant impact on the roofing industry, and it is expected to continue revolutionizing the way roofing projects are completed. With its advanced technology, versatility, speed, and ease of use, it has quickly become a must-have tool for roofing professionals around the world. As the company behind this game-changing machine continues to push the boundaries of innovation, it is clear that the Roofing Roll Former will play a key role in shaping the future of the roofing industry.

High Quality Rolling Forming Machine for Efficient Track Production

The track rolling forming machine is a crucial piece of equipment for many industries, and it is an invaluable tool for companies looking to streamline their production processes. This machine is used to create custom tracks for a variety of applications, including heavy machinery and industrial equipment.{Company Name} is a leading provider of track rolling forming machines, and they are known for their high-quality and reliable equipment. The company has been in business for over 20 years, and they have a strong reputation for delivering top-notch products and exceptional customer service.The track rolling forming machine offered by {Company Name} is designed to meet the specific needs of their customers. The machine is capable of creating tracks in a wide range of sizes and materials, and it can be customized to meet the unique requirements of each customer. This flexibility makes the machine an ideal choice for companies looking to improve their production processes and increase their overall efficiency.One of the key features of the track rolling forming machine is its advanced technology. The machine is equipped with state-of-the-art controls and automation systems, which allow for precise and efficient track forming. This technology also helps to reduce downtime and maximize productivity, making it an invaluable asset for companies with high production demands.In addition to its advanced technology, the track rolling forming machine offered by {Company Name} is also designed with durability and longevity in mind. The machine is built to withstand the rigors of industrial use, and it is constructed from high-quality materials that are designed to last. This means that companies can rely on their machine to perform consistently and reliably, even in demanding production environments.The track rolling forming machine from {Company Name} is also backed by comprehensive customer support and service. The company offers installation, training, and ongoing maintenance to ensure that their customers can get the most out of their equipment. This level of support is crucial for companies looking to maximize the return on their investment and ensure that their production processes run smoothly and efficiently.{Company Name} is proud to offer their track rolling forming machine to companies across the globe, and they have a strong track record of delivering exceptional results for their customers. The machine has been used in a wide range of applications, from agriculture to construction, and it has consistently proven to be a valuable asset for companies looking to improve their production processes.Overall, the track rolling forming machine offered by {Company Name} is a top-of-the-line piece of equipment that is designed to meet the specific needs of their customers. With its advanced technology, durability, and comprehensive customer support, the machine is an ideal choice for companies looking to streamline their production processes and improve their overall efficiency.

Glazed Tile Roll Forming Machine - Industrial Steel Rolling Machines for Metal Roofing Sheet Production

Title: ZhongTuoCN Revolutionizes Roofing Industry with Advanced Glazed Tile Roll Forming MachineIntroduction:ZhongTuoCN, a renowned leader in the steel rolling machine industry, has unveiled its latest product, the Color Steel Glazed Roof Tile Roll Forming Machine. This advanced machinery has revolutionized the roofing industry by enabling the efficient production of high-quality metal glazed tiles. With its cutting-edge technology and precision engineering, ZhongTuoCN is empowering manufacturers to meet growing demands for durable and aesthetically pleasing roofing solutions.1. Meeting the Rising Demand for Glazed Roofing Tiles:The demand for glazed roofing tiles has been steadily increasing due to their exceptional durability, weather resistance, and stunning visual appeal. Recognizing this trend, ZhongTuoCN's engineers have developed a state-of-the-art roll forming machine specifically designed to cater to this niche segment. Manufacturers can now produce glazed tiles efficiently, ensuring timely delivery and meeting customer expectations.2. Cutting-Edge Technology Enhances Efficiency:The Color Steel Glazed Roof Tile Roll Forming Machine stands out for its advanced features, guaranteeing optimal efficiency. Equipped with state-of-the-art automation technology, this innovative machine minimizes human intervention, reducing labor costs and increasing productivity. With high-speed forming capabilities, it guarantees a smooth and streamlined production process, allowing manufacturers to meet large-scale orders efficiently.3. Unparalleled Precision and Durability:ZhongTuoCN's Glazed Tile Roll Forming Machine is meticulously engineered to deliver unmatched precision and durability. Its robust frame, constructed from high-quality steel, ensures long-term stability and reliability. The rollers are made from top-grade materials, facilitating seamless tile formation without any deformities. This ensures that every finished tile exhibits consistent dimensions and exceptional surface quality.4. Flexibility in Tile Design and Customization:In addition to its standard features, the Color Steel Glazed Roof Tile Roll Forming Machine provides manufacturers with unparalleled flexibility in tile design and customization. By incorporating adjustable features in the machine, manufacturers can easily tailor the dimensions, profile, and curvature of the glazed tiles to meet various customer requirements. This adaptability sets ZhongTuoCN's machinery apart from its competitors and allows clients to offer unique and personalized roofing solutions.5. Strict Quality Control and After-Sales Support:ZhongTuoCN prioritizes quality control throughout the manufacturing process. Each component of the Glazed Tile Roll Forming Machine undergoes stringent testing to ensure optimal performance and durability. Additionally, ZhongTuoCN provides comprehensive after-sales support, including installation guidance, training programs, and 24/7 technical assistance. This commitment to customer satisfaction has earned the company an excellent reputation in the industry.Conclusion:With the introduction of the Color Steel Glazed Roof Tile Roll Forming Machine, ZhongTuoCN has reaffirmed its position as a pioneer in the steel rolling machine industry. This cutting-edge technology guarantees exceptional efficiency, precision, and customization options for manufacturers in the roofing sector. By empowering clients to meet the rising demand for glazed tiles, ZhongTuoCN is revolutionizing the roofing industry and offering an unparalleled solution for businesses worldwide.

Get a Glazed Tile Roof Panel Corrugation Machine for Durable and Attractive Rooftops

Glazed Tile Roof Panel Corrugation Machine revolutionizes the roofing industryThe roofing industry has undergone a significant transformation with advanced technology and efficient tools that have made the process faster, safer, and more durable. The Glazed Tile Roof Panel Corrugation Machine has emerged as one of the top tools in the roofing industry that has revolutionized the art of roofing. The machine has revamped the traditional way of roofing by transforming the way roofing panels are made, cut, and shaped.The Glazed Tile Roof Panel Corrugation Machine is the steel roll forming machine that shapes panels into various forms and sizes. The machine is designed to produce glazed tile panels with diverse profiles. The glazed tile panels add elegance to the building's structure and are durable, long-lasting, and attractive. The machine is designed to maintain the shape of the panel by forming it into a corrugated sheet.This machine has many features that help operators get their jobs done quickly and efficiently. The machine is easy to operate, and it can be customized to meet the needs of any roofing business. The machine is also highly efficient and can produce up to 30 meters of tiles per minute. Additionally, the machine is highly durable and has high-quality components that ensure longer lifespan.The Glazed Tile Roof Panel Corrugation Machine is an essential tool for all types of roofing businesses. The machine can be used to make the perfect curved or arched sheet panels for both commercial and residential buildings. The machine is also designed to handle both large and small projects, making it suitable for businesses of all sizes. Its high efficiency ensures that businesses can complete projects on time.The high-quality components of the Glazed Tile Roof Panel Corrugation Machine guarantee its longevity. The machine is made of materials that are resistant to rust and damage, ensuring a longer lifespan. Additionally, the machine is designed to be easy to maintain, reducing downtime and increasing productivity.The Glazed Tile Roof Panel Corrugation Machine is an excellent investment for any roofing business. Its high efficiency, durability, and low maintenance cost make it a cost-effective solution for any roofing project. The machine is designed to produce high-quality products, ensuring customer satisfaction and loyalty.About the CompanyOur company has been in the roofing industry for over a decade, and we understand the needs of roofing businesses. We have invested heavily in advanced technology and equipment to offer our customers the best products and services. We specialize in producing high-quality roofing sheet panels that are durable, attractive, and long-lasting. Our team of experts is highly skilled and experienced in the roofing industry, ensuring that we exceed our customer's expectations.Our primary focus is customer satisfaction, and we strive to meet our customer's needs by providing them with top-notch products, timely delivery, and excellent customer support. We take pride in our work and ensure that we go above and beyond to exceed our customer's expectations.ConclusionThe Glazed Tile Roof Panel Corrugation Machine is a game-changer in the roofing industry. It has revolutionized the traditional way of roofing and made the process faster, safer, and more durable. The machine's high efficiency, durability, and low maintenance cost make it an excellent investment for any roofing business. As a company, we understand the roofing industry's needs and have invested heavily in advanced technology to offer our customers the best products and services. Our team of experts is highly skilled and experienced, ensuring that we exceed our customer's expectations.

High-Quality Roof Panel Machine for Snap Lock Panels

Snap Lock Roof Panel Machine revolutionizes the roofing industryIn a major breakthrough for the roofing industry, a leading company has introduced a state-of-the-art Snap Lock Roof Panel Machine that is set to revolutionize the way roofs are installed and maintained. This remarkable piece of equipment has the potential to change the landscape of the roofing industry by streamlining the installation process and improving the overall quality and longevity of roofs.The Snap Lock Roof Panel Machine, developed by the innovative team at the company, is designed to produce high-quality snap lock roof panels that are not only durable and long-lasting, but also easy to install. This machine is equipped with advanced technology and precision engineering to ensure that the roof panels produced are of the highest standard and meet the specific requirements of each project.The company behind this groundbreaking technology is a leading manufacturer and supplier of roofing solutions, with a strong reputation for delivering top-quality products to customers across the globe. With a commitment to innovation and excellence, the company has consistently pushed the boundaries of what is possible in the roofing industry, and the introduction of the Snap Lock Roof Panel Machine is a testament to their dedication to driving advancements in the field.One of the key features of the Snap Lock Roof Panel Machine is its versatility and efficiency. The machine is capable of producing a wide range of snap lock roof panels in various sizes and designs, allowing for greater flexibility and customization in roofing projects. Furthermore, the automated nature of the machine ensures high levels of productivity, with the ability to produce a large volume of panels in a short amount of time, ultimately reducing installation time and labor costs for the customer.In addition to its impressive operational capabilities, the Snap Lock Roof Panel Machine also prioritizes durability and resilience in its output. The roof panels produced by this machine are constructed from high-quality materials that are engineered to withstand the harshest weather conditions and provide long-term protection for any structure. This focus on durability not only ensures the longevity of the roof, but also reduces the need for frequent maintenance and repairs, ultimately saving time and money for the customer in the long run.The introduction of the Snap Lock Roof Panel Machine marks a significant advancement in the roofing industry, and its potential impact is already being felt by industry professionals and customers alike. By offering a more efficient, cost-effective, and durable roofing solution, this machine is poised to set a new standard for roof installation and maintenance, and is expected to be widely adopted by contractors and builders looking to deliver superior results to their clients.As the demand for innovative and reliable roofing solutions continues to grow, the company is proud to lead the way with the Snap Lock Roof Panel Machine. With a strong commitment to pushing the boundaries of what is possible in the industry, the company is confident that this machine will not only meet the needs of today's roofing projects, but also set the stage for future advancements in the field.In conclusion, the introduction of the Snap Lock Roof Panel Machine represents a significant milestone in the roofing industry, offering a game-changing solution for contractors, builders, and customers. With its advanced technology, versatility, and focus on durability, this machine is set to transform the way roofs are installed and maintained, and is poised to become a standard-bearer for excellence in the field. As the company continues to push the boundaries of innovation and quality, the Snap Lock Roof Panel Machine stands as a testament to their commitment to delivering superior roofing solutions to customers around the world.

Sheet Metal Roll Forming: A Complete Guide to the Process

For Immediate Release:Sheet Metal Roll Forming Market To Showcase Continued Growth In Coming YearsThe global sheet metal roll forming market is expected to witness significant growth over the coming years, driven by the increasing demand for efficient and cost-effective manufacturing processes in various industries such as automotive, construction, aerospace, and others. Sheet metal roll forming is a continuous bending operation in which a long strip of sheet metal is passed through a series of rolls and progressively formed into the desired shape.The rise in construction activities, especially in emerging economies, is expected to be a major driver for the growth of the sheet metal roll forming market. As urbanization continues to increase, the demand for commercial and residential buildings is also on the rise, leading to increased use of sheet metal products in construction applications. Additionally, the automotive industry is also expected to contribute to the growth of the market, with an increasing focus on lightweight and fuel-efficient vehicles.Furthermore, technological advancements in sheet metal roll forming processes are also expected to drive market growth. Manufacturers are increasingly investing in advanced roll forming machines and systems to improve efficiency, reduce lead times, and enhance productivity. These advancements are expected to make sheet metal roll forming a more attractive option for a wide range of applications.Competitive LandscapeThe global sheet metal roll forming market is highly competitive and fragmented, with the presence of several key players. Companies are focusing on strategic partnerships, product launches, and acquisitions to strengthen their market position and expand their product portfolio. For instance, {Company name} is one of the leading players in the sheet metal roll forming market, offering a wide range of roll forming machines and systems to cater to various industries.Company Introduction:{Company name} is a global leader in the design, manufacture, and supply of sheet metal roll forming equipment. With over 50 years of experience, the company has established a strong reputation for delivering high-quality, reliable, and efficient roll forming solutions to its customers worldwide. {Company name} offers a comprehensive range of roll formers, including standard and custom-designed systems, to meet the unique requirements of different industries.The company's commitment to innovation and continuous improvement has enabled it to stay at the forefront of the sheet metal roll forming market. {Company name} continuously invests in research and development to develop advanced roll forming technologies that deliver superior performance and cost-effectiveness. The company's dedicated team of engineers and technicians work closely with customers to understand their specific needs and provide tailored solutions that optimize production processes and enhance product quality.In addition to offering cutting-edge roll forming equipment, {Company name} also provides comprehensive technical support, training, and after-sales services to ensure customer satisfaction. The company's global presence and strong distribution network enable it to serve customers in various regions with unmatched expertise and support. With a focus on customer-centric approach and a commitment to excellence, {Company name} has become a trusted partner for businesses looking to enhance their sheet metal roll forming capabilities.OutlookThe global sheet metal roll forming market is poised for significant growth in the coming years, driven by the increasing adoption of advanced roll forming technologies across various industries. As demand for efficient and cost-effective manufacturing processes continues to rise, sheet metal roll forming is expected to play a crucial role in meeting the needs of diverse applications. With leading players such as {Company name} driving innovation and setting new industry standards, the market is expected to witness continued evolution and expansion in the foreseeable future.

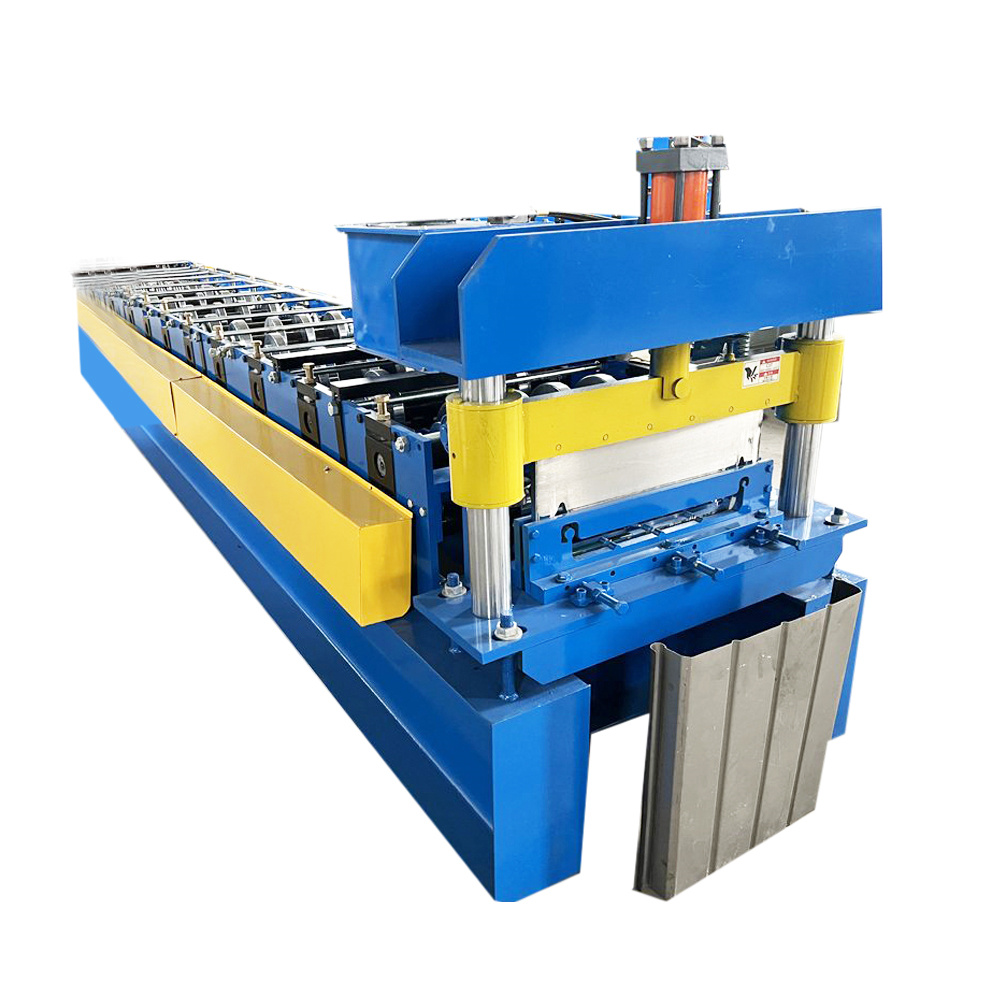

High-Quality Double Layer Roll Forming Machines at Low Prices

: The Solution for Improved Efficiency and PerformanceAs the global demand for quality steel roofing materials continues to increase, so does the need for efficient and high-performance roll forming machines. One such machine that has proven to be a game-changer in the metal roofing industry is the double layer color steel roll forming machine. In this blog post, we will delve deep into the features and benefits of this machine.What is a Double Layer Color Steel Roll Forming Machine?A double layer color steel roll forming machine is a type of roll forming equipment designed to produce two different metal sheets simultaneously. This machine is engineered to incorporate two sets of roll forming systems that work independently to produce two types of profiles without changing the roll tooling.The machine consists of a decoiling system, a double-layer roll former, a hydraulic cutting system, a programmable controller, and a stacking system. With its advanced design, the double layer roll forming machine can produce metal roofing panels at an incredible speed and with remarkable accuracy.Why Choose a Double Layer Roll Forming Machine?There are several reasons why a double layer roll forming machine is a smart investment for metal roofing manufacturers. Firstly, this machine simplifies processes and reduces downtime by producing two different profiles simultaneously. This approach saves valuable time for manufacturers, making them more productive and efficient.Moreover, the double layer roll forming machine produces consistent and uniform sheets. This ensures that the metal sheets meet the precise requirements of the end-user and helps to eliminate defects such as scratches, dents, or uneven surfaces. As a result, this leads to higher customer satisfaction and fewer product returns, reducing the overall costs.Another benefit of the double layer roll forming machine is its versatility. It can manufacture a wide range of metal roofing profiles such as corrugated sheets, trapezoidal sheets, and standing seam panels. This means that manufacturers can cater to various customer needs and demands while remaining competitive in the market.Features of a Double Layer Roll Forming MachineThe double layer roll forming machine comes with several features that make it stand out from other roll forming machines. Some of these features include:1. Multiple Profiles: The machine can produce up to 2 different profiles simultaneously, offering unmatched versatility and flexibility to manufacturers.2. High Precision: With its advanced hydraulic cutting system and programmable controller, the machine can produce metal sheets with high precision and without material wastage.3. High Efficiency: The machine can produce up to 35 meters of metal roofing sheets per minute, making it a highly efficient and profitable machine for metal roofing manufacturers.4. Easy to Operate: The double layer roll forming machine comes with a user-friendly interface that makes it easy for operators to set up and control the machine. It also requires low maintenance, reducing downtime, and repair costs.5. Robust and Durable: The machine is made of high-quality steel and other durable materials, ensuring it can withstand harsh working conditions and last for a long time.ConclusionThe double layer roll forming machine is an innovative and efficient solution to the increasing demand for quality metal roofing sheets. It offers manufacturers unmatched flexibility, efficiency, and precision, making it a highly profitable investment. Its advanced features, ease of maintenance, and durability are essential components needed for a successful metal roofing business. So, if you are searching for a reliable roller forming machine, get in touch with a double layer roll forming machine supplier today.

The Distinction between Slitting Machines and Cut-to-Length Machines for Steel Coils

Title: Maximizing Efficiency and Cost Savings: Understanding the Difference Between Slitting Machines and Cut-to-Length MachinesIntroduction:In today's fast-paced manufacturing industry, optimizing production processes while minimizing costs is essential to remain competitive. When it comes to cutting steel coils to specific dimensions, both slitting machines and cut-to-length machines play a crucial role in achieving these objectives. In this blog post, we will explore the differences between these two machines and how they can help you streamline your manufacturing operations. Keywords: slitting machine, cut-to-length machine, steel coils, production processes, cost savings, manufacturing operations1. Understanding the Slitting Machine:A slitting machine is specifically designed to cut wide steel coils into narrower strips. It is ideal for applications that require multiple narrow coils of varying widths. The slitting process involves unwinding the master coil, passing it through rotating circular knives, and rewinding the slit strips onto individual smaller coils. By adjusting the slitter's settings, you can achieve precise dimensions according to your specific requirements. This versatility makes slitting machines a popular choice for various industries, including automotive, construction, and steel fabrication. 2. Exploring the Cut-to-Length Machine:On the other hand, a cut-to-length machine is primarily used to cut steel coils into individual sheets of predetermined lengths. This machine eliminates the need for rewinding smaller coils, ensuring that the desired dimensions are produced efficiently in a single pass. Cut-to-length machines are highly advantageous when it comes to producing accurately-sized sheets for applications such as roofing, flooring, and paneling. By choosing the suitable settings, you can achieve consistent cuts, reducing material waste and improving overall productivity.3. Cost Savings and Material Efficiency:By applying slitting and cut-to-length techniques to the manufacturing process, you can significantly reduce material costs and inventory. Using standard-size steel coils allows you to take advantage of bulk purchasing at lower prices. By slitting or cutting these coils to precise dimensions, you eliminate the need for specialized coil sizes, thereby reducing inventory expenses. Furthermore, both techniques minimize material waste, allowing you to efficiently utilize every part of the coil, resulting in additional cost savings.4. Factors Influencing Machine Selection:When deciding whether to invest in a slitting machine or a cut-to-length machine, several factors need to be considered. These factors include the desired end product, production volume, speed requirements, material thickness, and available floor space. For businesses with higher production volumes and a requirement for multiple narrow strips, a slitting machine would be a preferred choice. Conversely, if you primarily need accurately sized sheets with consistent lengths, a cut-to-length machine would be more suitable.5. Enhancing Production Efficiency:Both slitting and cut-to-length machines offer significant advantages in enhancing production efficiency. These machines are often equipped with advanced features such as automated controls, precision cutting tools, and real-time monitoring systems. These features enable faster setup times, reduce operator errors, and enhance overall productivity. Additionally, the integration of these machines with other process automation technologies can further streamline the production line, leading to optimized efficiency.Conclusion:Slitting machines and cut-to-length machines play a vital role in the manufacturing industry by enabling cost-effective customization of steel coils. Understanding their differences and choosing the right machine for your specific production requirements is crucial. The utilization of these machines can lead to substantial cost savings, improved material efficiency, and streamlined manufacturing operations. By investing in the appropriate machinery and adopting efficient production techniques, businesses can thrive in today's competitive marketplace.Keywords: slitting machine, cut-to-length machine, steel coils, production requirements, cost-effective customization, manufacturing operations, streamlined productivity.

Competitive Intelligence by Key Players in the Automatic Roll Forming Machine Market: Global Market Analysis and Size

Automatic Roll Forming Machine Market: Increasing Industrialization Driving Demand for C/Z Purlin Roll Forming MachinesThe global Automatic Roll Forming Machine market is expected to witness robust growth in the coming years, driven by increasing industrialization across the globe. The Automatic Roll Forming Machine is a highly versatile equipment that is used in industries such as construction, automotive, electronics, and aerospace, among others. It is used for forming metal sheets and strips into different shapes and sizes. Among the various types of Roll Forming Machines, C/Z Purlin Roll Forming Machine is a popular choice for manufacturing structures that require strong supports for roofing, cladding, and walls.C/Z Purlin Roll Forming Machine is a type of Roll Forming Machine that is designed specifically for producing C-shaped and Z-shaped purlins. These purlins are used for making pre-engineered steel buildings, industrial sheds, warehouses, and other structures. The machine works by feeding a strip of metal through a series of rollers that shape the metal into the desired profile. The final product is a strong, lightweight, and durable purlin that can withstand heavy loads and adverse weather conditions.Key Market Players in Automatic Roll Forming Machine MarketThe key market players in the Automatic Roll Forming Machine market include Bradbury Group, Framing Tech, Formtek Group, Gasparini Industries, HILALMAK, Howick, Isolaminas, JET USA, Knauer Engineering, L.B. Bohle Maschinen + Verfahren, M.Torres, Onward Machinery, PEP brainin, Taicang Keboer, TOX Pressotechnik, TRL Krosaki Refractories Limited, Xiamen Zheng Liming Metallurgical Machinery, and Yoder.Market SegmentationThe global Automatic Roll Forming Machine market can be segmented based on product type, application, and region.Based on Product Type, the market can be segmented into:• C/Z Purlin Roll Forming Machine• Corrugated Sheet Roll Forming Machine• Tile Roll Forming Machine• OthersBased on Application, the market can be segmented into:• Construction• Automotive• Electronics• Aerospace• OthersBased on Region, the market can be segmented into:• North America• Europe• Asia-Pacific• Middle East and Africa• South AmericaRegional AnalysisThe Asia-Pacific region is expected to dominate the Automatic Roll Forming Machine market in the forecast period, owing to the increasing demand for industrialization in countries such as China, India, and Japan. The region also has a large base of manufacturers and a significant consumer base for Roll Forming Machines. The North American and European markets are also expected to witness steady growth due to the increasing demand for lightweight and durable materials in the construction and automotive industries.ConclusionThe Automatic Roll Forming Machine market is expected to witness robust growth in the coming years, owing to the increasing demand for lightweight and durable materials in the construction, automotive, electronics, and aerospace industries. C/Z Purlin Roll Forming Machines are expected to witness significant demand, owing to the increasing demand for pre-engineered steel buildings, industrial sheds, and warehouses. The Asia-Pacific region is expected to dominate the market, owing to the increasing demand for industrialization in the region. The key market players in the market are Bradbury Group, Framing Tech, Formtek Group, Gasparini Industries, HILALMAK, among others.