Boost Your Roofing Projects with a High-Quality Corrugated Iron Machine

By:Admin

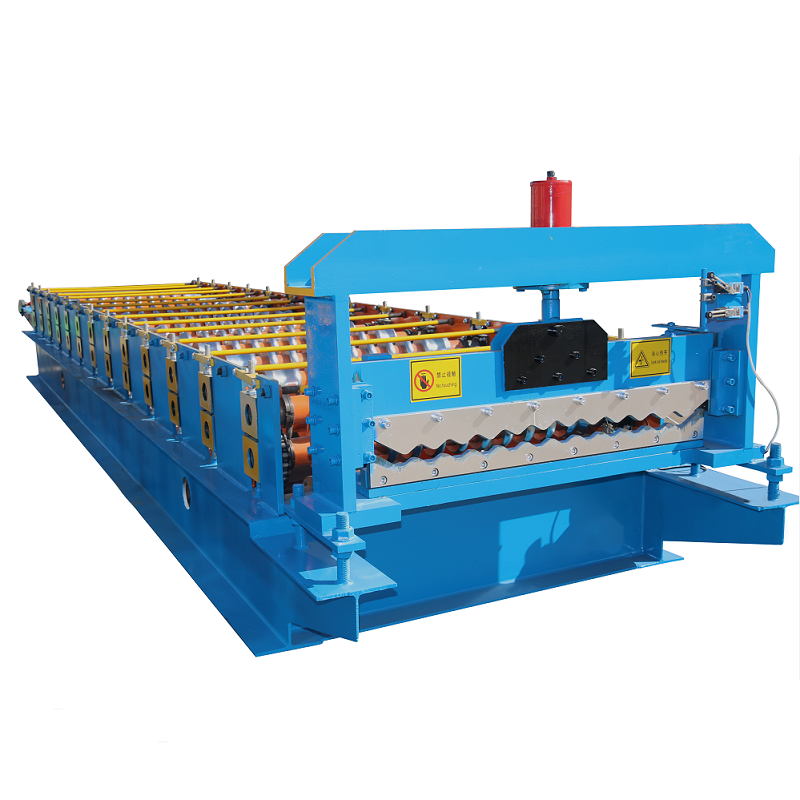

The machine boasts an innovative design that enables it to produce high-quality corrugated iron sheets quickly and efficiently. Its robust frame is made of high-quality materials to support its heavy-duty operations. The machine's internal structure has been engineered to perfection, ensuring that it operates with minimal wear and tear. Additionally, the machine is fitted with top-of-the-line electrical and mechanical parts to ensure its durability and reliability.

The company behind this revolutionary machine is one of the leading manufacturers of industrial equipment for the construction sector. They are known for their cutting-edge machinery, which is designed to streamline construction processes and boost productivity. With years of experience in the industry, they understand their customers' needs and demands and strive to offer them the best possible solutions.

The Corrugated Iron Machine's features highlight its versatility and adaptability. It can produce corrugated sheets of varying thickness, length, and width, ensuring that it satisfies the diverse needs of its users. Through a simple yet intuitive interface, the machine can be easily adjusted to accommodate different settings, making it ideal for small and large-scale manufacturers. Moreover, the machine's energy-efficient nature ensures that it consumes minimal electricity, making it an eco-friendly option.

One of the primary benefits of the Corrugated Iron Machine is its ability to increase productivity and reduce labour costs. With the traditional method, producing a single corrugated sheet could take hours and required a team of workers. However, with this machine, a single operator can produce up to hundreds of corrugated sheets within a few hours. It is highly beneficial for manufacturers as it enables them to increase their production output while minimizing labour costs.

The Corrugated Iron Machine's low maintenance requirement is a testament to its robustness and reliability. The machine has been designed to operate with minimal maintenance. Its internal parts are easily accessible should any maintenance need arise, and its user-friendly interface ensures that operators can carry out routine maintenance without any hassle.

The machine's ergonomic design ensures that it is easy to operate and maintain. Its built-in safety features ensure that operators are safe while operating the machine. Additionally, the machine's structure is designed to reduce noise levels, creating a comfortable working environment for the operator.

To conclude, the introduction of the Corrugated Iron Machine is a significant milestone for the construction industry. Its ability to produce high-quality corrugated sheets quickly and efficiently has revolutionized the manufacturing process. The machine's durability, low maintenance requirement, and energy-efficient nature not only benefit the user but also the environment. As the demand for sturdy construction materials continues to rise, the Corrugated Iron Machine is sure to be a game-changer, ensuring that manufacturers can keep up with the increasing demand.

Company News & Blog

Increased Demand for Curving Rolls for Corrugated Iron Sparks CNC Corro Curving Machine Sourcing

Title: Acra Machinery Meets Increasing Demand for Corrugated Iron Curving RollsIntroduction (100 words):Acra Machinery, a renowned supplier of industrial machinery, has recently experienced a surge in requests for curving rolls specifically designed to suit Corrugated Iron. Responding to market demand, the company has successfully sourced a state-of-the-art computer numerical control (CNC) curving machine. This cutting-edge technology, devoid of the brand name, ensures precise and efficient production of Corrugated Curving Rolls. Acra Machinery's ability to meet this rising demand bolsters the company's reputation as a reliable provider in the industrial machinery sector.Body (600 words):1. Rising Demand for Corrugated Iron Curving Rolls (150 words):Corrugated iron is widely used in the construction and architectural industries due to its durability, strength, and cost-effectiveness. As the demand for innovative and aesthetically pleasing architectural solutions continues to grow, there has been an increasing requirement for curved corrugated iron sheets. Curved corrugated iron provides enhanced structural integrity and design flexibility, enabling architects, builders, and designers to create unique and visually appealing structures.Recognizing this demand, Acra Machinery has been inundated with numerous requests for curving rolls specifically designed to suit corrugated iron. While traditional manual methods were previously employed to curve such rolls, the ever-expanding market required a more efficient and accurate solution. To meet these evolving demands, Acra Machinery sought to acquire a full CNC curving machine capable of meeting both functional and aesthetic requirements.2. Sourcing a State-of-the-Art Curving Machine (150 words):To address the increasing demand for curving rolls tailored to corrugated iron, Acra Machinery proactively researched and sourced a full CNC curving machine. This computer numerical control technology facilitates automated and precise curving of corrugated iron sheets. By removing the brand name, it is evident that Acra Machinery prioritizes the functionality and quality of the curving machine, ensuring optimal production outcomes for their clientele.The CNC curving machine acquired by Acra Machinery operates on advanced software, allowing for comprehensive customization options. Users can adjust the curvature, radius, and dimensions of the corrugated iron sheets according to their unique requirements. This versatility enables architects and builders to explore innovative design possibilities, breathing life into architectural visions and pushing the boundaries of construction.3. Unmatched Precision and Efficiency (150 words):The integration of the CNC curving machine into Acra Machinery's production processes has revolutionized the precision and efficiency with which corrugated iron curving rolls are manufactured. Through the automation provided by the CNC technology, manual errors are minimized, ensuring consistently accurate results.The CNC curving machine controls every aspect of the rolling process, optimizing efficiency and reducing production time significantly. This streamlined workflow positively impacts the delivery timelines for customers, allowing them to meet project deadlines more effectively.4. Strengthening Acra Machinery's Market Position (150 words):By successfully meeting the industry's escalating demand for curving rolls for corrugated iron, Acra Machinery has strengthened its position as a trusted provider of industrial machinery. The company's ability to source and utilize advanced CNC technology showcases its commitment to customer satisfaction and technological advancement. Acra Machinery's dedication to innovation and meeting market needs has not only elevated their status but also established them as an industry leader.Furthermore, by investing in state-of-the-art CNC curving technology, Acra Machinery is empowering architects, builders, and designers to realize their creative visions with precision. The enhanced opportunities for experimentation offered by these curving rolls will undoubtedly inspire new architectural designs and constructions.Conclusion (100 words):Acra Machinery's successful acquisition and utilization of a full CNC curving machine to cater to the growing demand for corrugated iron curving rolls marks a significant achievement in the industry. The company's commitment to meeting market needs and deploying modern technologies has bolstered its reputation as a trusted provider in the industrial machinery sector. With the introduction of these advanced curving rolls, Acra Machinery has enabled architects and builders to explore new possibilities for efficient and aesthetically pleasing architectural designs, setting the stage for future innovation in the construction industry.

Roll Forming Machine for C/Z/U Channel Interchange: Discover China's Latest Product Innovation

Roll forming machines have become an essential tool in the manufacturing industry. They are used to create metal sheets of different shapes and sizes according to specific manufacturing requirements. One such machine that has gained immense popularity in recent times is the C/Z/U Channel Interchanged Roll Forming Machine.If you're in search of a reliable and efficient roll forming machine, look no further than China-Glorious.com. Here, you will find a range of machines that are designed to cater to different manufacturing needs. The C/Z/U Channel Interchanged Roll Forming Machine, in particular, has numerous features and benefits that make it a great investment for your business.What is a C/Z/U Channel Interchanged Roll Forming Machine?A C/Z/U Channel Interchanged Roll Forming Machine is a roll forming machine that can produce C-shaped, Z-shaped, and U-shaped channels from coiled steel. These channels are used in the construction of roofs, walls, flooring, and other structural components. The machine includes a series of rollers and cutting tools that produce the desired shape by gradually bending and forming the metal strip.Why Choose a C/Z/U Channel Interchanged Roll Forming Machine?The C/Z/U Channel Interchanged Roll Forming Machine is a versatile piece of equipment that comes with a host of benefits. Here are some of the reasons why you should consider investing in one:1. Faster Production - With a C/Z/U Channel Interchanged Roll Forming Machine, you can produce channels at a faster speed compared to traditional methods. This increased speed helps in meeting the demands of customers within a shorter time frame.2. Consistent Quality - The machine ensures consistent quality in every channel produced, which is essential in the construction industry. A consistent quality output also reduces waste, ensuring maximum utility of the raw materials.3. Cost-Effective - The machine requires less labor, materials, and maintenance costs, making it a cost-effective solution to mass-production. This means that investing in a C/Z/U Channel Interchanged Roll Forming Machine is a great way to save your business money over the long term.4. Flexibility - The machine can produce different sizes and shapes of channels, equipping manufacturers with more flexibility in their production line. Plus, a varied shape and size offering ensures that the manufacturer is well positioned to meet the needs of different customers.5. Durable - The machine is made from high-quality materials, so it has a longer lifespan than other equipment used for shaping metal channels. Therefore, making it an excellent return on investment due to an extended period of usage.6. Easy to Use - The machine comes with a well-detailed user manual that makes it easy to set up and operate.In conclusion, the C/Z/U Channel Interchanged Roll Forming Machine offers numerous advantages for manufacturers looking to increase their production output in a cost-effective and efficient manner while ensuring consistent quality. At China-Glorious.com, you can find a high-quality resilient channel rolling machine at an affordable price. Opt for this machine and take your production capabilities to the next level.

Top-rated Roll Forming Machine for Roofing Sheet Production: Ultimate Guide

Title: Roofing Sheet Roll Forming Machine Redefines the Manufacturing ProcessIntro:Innovation has always been at the forefront of the manufacturing industry, constantly pushing the boundaries of what is possible. One such groundbreaking invention is the Roofing Sheet Roll Forming Machine developed by an industry-leading company, revolutionizing the roofing manufacturing process. This state-of-the-art machine not only enhances productivity but also ensures superior quality and durability of roofing sheets. With its introduction into the market, the way roofing materials are produced is set to change forever.I. Need for Revolutionizing Roofing Sheet Manufacturing: Roofing sheets are an essential component in the construction industry, providing protection against harsh weather conditions while enhancing the aesthetic appeal of buildings. Traditionally, manufacturing such sheets involves many time-consuming and labor-intensive processes, resulting in increased costs and longer production time. However, with the advent of the Roofing Sheet Roll Forming Machine, these challenges are effectively addressed.II. Features and Functionality:This innovative machine consists of advanced technology and precision engineering, enabling the rapid and efficient transformation of raw materials into high-quality roofing sheets. Its automatic operation and computer-controlled interfaces eliminate human errors and reduce reliance on manual labor. The machine is equipped with a robust frame and special rollers that shape metal sheets into the desired dimensions and profiles sought by customers.III. Enhanced Efficiency and Productivity:The Roofing Sheet Roll Forming Machine significantly streamlines the production workflow, offering increased efficiency and productivity gains. By automating various processes, including sheet cut to length, roll forming, and sheet stacking, the machine enables swift and continuous manufacturing without compromising on quality. Additionally, its high-speed capabilities guarantee faster output, resulting in reduced lead times and improved customer satisfaction.IV. Superior Quality and Customizability:One of the key advantages of this machine is its ability to consistently produce roofing sheets of exceptional quality. By utilizing precise measurements and automated control systems, it ensures accuracy and consistency in the shape, size, and thickness of each sheet. Moreover, the machine allows for customization, offering customers a wide range of profiles, surface finishes, and color options according to their individual requirements.V. Economic and Environmental Benefits:The Roofing Sheet Roll Forming Machine not only benefits manufacturers but also has a positive impact on the economy and the environment. Its efficiency and increased productivity lead to cost savings by reducing labor requirements and optimizing material usage. Furthermore, the machine promotes sustainability by minimizing scrap and waste, contributing to the overall reduction of carbon footprint associated with the manufacturing process.VI. Market Impact and Future Prospects:With its introduction into the market, the Roofing Sheet Roll Forming Machine is expected to disrupt the roofing industry significantly. Manufacturers can now meet the increasing demand for high-quality roofing materials more efficiently, reducing costs and expanding production capacities. Additionally, the machine's flexibility allows for easy adaptation to emerging trends and customer preferences, ensuring its relevance in the ever-evolving construction industry.Conclusion:The Roofing Sheet Roll Forming Machine, developed by a renowned company, has ushered in a new era in roofing sheet manufacturing. Its innovative design and advanced features enable enhanced efficiency, superior quality, and customization options previously unheard of in the industry. This cutting-edge technology will undoubtedly transform the way roofing materials are manufactured, paving the way for increased productivity, reduced costs, and sustainable practices. As the construction industry continues to evolve, this machine is poised to play a pivotal role in meeting the demands of an ever-changing market.

Glazed Tile Roll Forming Machine for Metal Roofing Sheet Production

If you are in search for a reliable and efficient Glazed Tile Roll Forming Machine, then Dahezb Metal has got you covered. Dahezb Metal specializes in designing and manufacturing high quality auto glazed tile forming machines that produce metal roof tiles of 0.3-0.6mm thickness. They specialize in Aluminum roofing step tile machines, glazed roll forming machines, and glazed tile roll forming machines that are specifically designed for making glazed tiles for roofing sheets.One of the unique features of the Glazed Tile Roll Forming Machine from Dahezb Metal is its ability to effectively remove brand names from the roofing sheet during production. This feature is particularly important for customers who need to produce roofing sheets for their own brand without having to purchase expensive equipment or worry about legal issues.The Glazed Tile Roll Forming Machine is a versatile production machine that can be used to produce a wide range of roofing sheets including Aluminum, Color Steel, and Glazed Steel tiles. It is a durable and high-performance machine that is designed and built with high-quality materials and advanced technology to ensure accuracy, precision, and speed.With a production capacity of up to 15 meters per minute, the Glazed Tile Roll Forming Machine from Dahezb Metal is one of the most efficient and profitable investments for anyone looking to venture into the roofing sheet production business. The machine is easy to operate, maintain, and requires minimal technical skills to effectively run and produce high-quality roofing sheets.The Glazed Tile Roll Forming Machine is designed with safety in mind. It features an emergency stop button and other safety features to ensure that operators are always protected from potential hazards. The machine also comes with a user-friendly interface that allows operators to easily adjust the production settings and monitor the production process.In conclusion, if you are looking for an efficient and reliable Glazed Tile Roll Forming Machine, then Dahezb Metal Glazed Tile Roll Forming Machine is the perfect choice. It is a high-performance machine that is designed to produce high-quality roofing sheets in an efficient, cost-effective, and safe manner. It is a valuable investment that guarantees a high return on investment and long-term profitability. So, if you want to get ahead in the roofing sheet production business, the Glazed Tile Roll Forming Machine from Dahezb Metal is your best bet.

Highly Accurate CNC Milling of Aluminum Extrusion Profiles

Aluminum Extrusion Milling Machine: Revolutionizing Precision and EfficiencyAluminum extrusion has become an integral part of various industries due to its lightweight, high strength, and versatility. From automotive to aerospace, electronics to construction, the demand for aluminum extrusion profiles is skyrocketing. However, in order to meet the ever-increasing demands, manufacturers need cutting-edge machinery and techniques. This is where aluminum CNC milling machines come into play.Precision is KeyTo produce high-quality aluminum extrusion profiles, precision is of utmost importance. Any slight deviation from the desired dimensions can lead to product failure. This is where the CNC (Computer Numerical Control) milling machines step in. These advanced machines use computer-controlled systems to execute complex milling operations with unmatched accuracy.The precision offered by aluminum CNC milling machines allows manufacturers to create intricate designs and shapes with high repeatability. From simple profiles to complex geometries, these machines can handle it all. This not only ensures consistency in the final product but also minimizes wastage, saving valuable resources and costs.High-Speed PerformanceApart from precision, speed is another crucial factor that determines the efficiency of aluminum extrusion production. Traditional machining methods are time-consuming, limiting the manufacturing capacity. In contrast, CNC milling machines offer enhanced productivity by virtue of their high-speed performance.Equipped with powerful spindles and cutting tools, CNC milling machines can quickly remove material from the aluminum billet, resulting in faster production cycles. The automated nature of these machines eliminates manual errors and speeds up the overall manufacturing process. This enables manufacturers to cater to large volumes of orders while maintaining the desired quality standards.Advanced Features for Enhanced FunctionalityCNC milling machines for aluminum extrusion profiles are equipped with a wide range of advanced features that further enhance their functionality. One such feature is the multi-axis capability. These machines can perform milling operations on multiple axes simultaneously, allowing for complex, three-dimensional profiling. This opens up a whole new world of design possibilities, expanding the horizons of aluminum extrusion applications.Furthermore, the CNC systems in these machines can be programmed to operate in a variety of modes. Whether it is contour milling, pocket milling, or face milling, the CNC milling machines can effortlessly handle all operations, ensuring seamless production processes.Sourcing High-Quality Aluminum Extrusion Milling MachinesTo experience the benefits of precision and efficiency offered by aluminum CNC milling machines, it is imperative to collaborate with reliable suppliers. When searching for OEM aluminum extrusion profile, high precision aluminum CNC milling suppliers, one name that stands out is aluminum-extrusion.At aluminum-extrusion, we specialize in providing top-notch aluminum extrusion profiles and CNC milling machines. With a focus on quality and affordability, we offer a wide range of products to cater to diverse industry requirements. Our expertise lies in delivering OEM aluminum extrusion profiles that meet the highest standards of precision and accuracy.ConclusionIn the fast-paced manufacturing industry, efficiency and precision are critical factors that can make or break a business. Aluminum extrusion milling machines offer the perfect solution to meet these demands. With their ability to deliver high precision, superior speed, and advanced functionality, these machines revolutionize the aluminum extrusion process.Collaborating with reputable suppliers like aluminum-extrusion ensures access to high-quality products that not only drive efficiency but also maintain the desired quality standards. So, embrace the power of aluminum CNC milling machines and unlock a world of possibilities for your aluminum extrusion profile manufacturing needs.

Innovative Ways to Incorporate Corrugated Metal into Your Home Design

Corrugated Metal Ideas For The Home: A Stylish and Sustainable ChoiceIn today's world, where sustainability and functionality are valued more than ever, it's no surprise that corrugated metal has become a popular choice for home décor and design. With its many versatile uses and inherent qualities, corrugated metal has emerged as a go-to option for homeowners looking to add a unique touch to their living spaces. From roofing to wall accents, furniture to garden sheds, this lightweight, portable, and corrosion-resistant material offers endless possibilities. In this blog post, we explore some innovative corrugated metal ideas for the home, highlighting its benefits, design inspirations, and the ease of using corrugated metal rollers for various projects.Benefits of Corrugated Metal in Home Design:1. Lightweight and Portable: Corrugated metal sheets or rolls are incredibly lightweight, making them easy to handle and transport. This feature is particularly beneficial for homeowners who might want to install or relocate structures and accents periodically. Whether you're building a garden shed, a privacy screen, or an outdoor kitchen, the lightweight nature of corrugated metal allows for effortless installation and customization.2. Corrosion-Resistant and Durable: When it comes to long-lasting materials, corrugated metal is a winner. Its resilient composition provides excellent resistance against corrosion, rust, and other environmental factors. Corrugated metal not only withstands harsh weather conditions but also ensures your investment will last for years to come. This durability makes it a cost-effective choice, eliminating the need for frequent repairs or replacements.3. Economical and Low Maintenance: Corrugated metal is a budget-friendly option that offers significant savings in the long run. Its affordable price, coupled with its longevity, reduces maintenance and replacement costs over time. Unlike traditional roofing materials that may require constant upkeep, corrugated metal requires minimal maintenance, making it an ideal choice for homeowners looking for both cost-effectiveness and durability.4. Eco-Friendly and Recyclable: Sustainability is a key consideration for many homeowners today. With corrugated metal, you can rest assured that you are making an eco-conscious choice. In addition to being easy to recycle, corrugated metal is often made from recycled materials itself. By utilizing this material in your home design, you can reduce your carbon footprint and make a positive impact on the environment.Design Inspirations and Ideas:1. Roofing: Corrugated metal roofs are popular for their sleek and modern aesthetic. The distinctive ridges of the metal add character to any architectural style, be it contemporary or industrial. Moreover, the durability of corrugated metal ensures that your roof will remain intact and visually appealing for years to come. Its lightweight nature also reduces stress on the overall structure of the building.2. Walls and Facades: Corrugated metal can be used to create stunning wall accents, both indoors and outdoors. Whether it's a feature wall in your living room or an eye-catching façade for your home exterior, the combination of corrugated metal and other materials, such as wood or concrete, can create a visually striking contrast. Additionally, you can choose to paint or patina the metal to further enhance its aesthetic appeal.3. Furniture and Décor: Corrugated metal can be incorporated into furniture design, adding an industrial and rustic touch to your home. From coffee tables to kitchen countertops, the possibilities are endless. Its durability and resistance to wear make it a great choice for high-traffic areas or outdoor furniture, where longevity is essential. Corrugated metal accents, such as barn doors or room dividers, can also lend a trendy farmhouse vibe to any interior space.4. Garden Sheds and Structures: Want to add a touch of elegance to your garden or backyard? Consider using corrugated metal in constructing garden sheds, pergolas, or fences. The fascinating texture and sleek lines of the metal will instantly elevate the overall look of your outdoor space. Moreover, its lightweight nature ensures effortless installation and easy customization options such as painting or staining to match your existing garden theme.Using Corrugated Metal Rollers for DIY Projects:While corrugated metal sheets offer a wide range of benefits and visual appeal, the process of shaping and creating custom sizes can be challenging. This is where corrugated metal rollers come into play. These tools are specifically designed to shape and roll corrugated metal sheets according to your desired specifications. They provide the flexibility and accuracy needed to achieve precise results. Whether you're looking to create a curved accent wall or custom roofing, corrugated metal rollers allow for easy manipulation and ensure a smooth, professional finish.In conclusion, corrugated metal has become a favored choice for homeowners looking to incorporate sustainability, style, and longevity into their home design. Its lightweight, corrosion-resistant, and eco-friendly qualities make it an ideal material for various projects. From roofs to walls, furniture to garden accents, the possibilities are endless when it comes to using corrugated metal in your home. By utilizing corrugated metal rollers, you can unleash your creativity and easily shape this versatile material to fit your unique visions. So, why not consider adding a touch of industrial charm to your living space? Embrace the corrugated metal trend and make a bold statement in your home today.

High-quality Roof and Tile Roll Forming Machines for Efficient Roofing Solutions

Roof Tile Roll Forming Machine: Revolutionizing the Roofing IndustryIn today's rapidly evolving construction industry, innovative technology is constantly paving the way for more efficient and effective processes. One such groundbreaking technology is the Roof Tile Roll Forming Machine, a game-changer in the field of roofing. This advanced machinery has revolutionized the way roofs are installed, providing a faster and more cost-effective solution for both residential and commercial projects.Before the advent of the Roof Tile Roll Forming Machine, traditional roofing methods required skilled laborers to manually cut, shape, and assemble individual tiles. This process was not only time-consuming but also prone to errors, resulting in unnecessary wastage of materials and increased costs. However, with the introduction of the Roof Tile Roll Forming Machine, all these drawbacks have become a thing of the past.The Roof Tile Roll Forming Machine utilizes state-of-the-art technology that allows for the precise and automated production of roof tiles. The machine consists of a series of rollers and tooling stations that gradually shape the metal coils into perfectly formed tiles. This process eliminates the need for manual cutting and shaping, significantly reducing labor costs and improving overall efficiency.One of the key advantages of the Roof Tile Roll Forming Machine is its versatility. The machine can produce a wide range of tile profiles, catering to the diverse needs and preferences of customers. From classic clay tiles to modern metal alternatives, the Roof Tile Roll Forming Machine can effortlessly produce high-quality tiles in various shapes, sizes, and textures. This flexibility not only enhances design possibilities but also ensures that customers can find the perfect fit for their specific roofing requirements.Additionally, the Roof Tile Roll Forming Machine offers excellent precision and consistency in tile production. The automated process guarantees consistent tile dimensions, ensuring a seamless end result. The machine's robust build and advanced control systems allow for high-speed production without compromising on quality. This not only enhances the overall efficiency of the roofing process but also leads to long-lasting and aesthetically pleasing roofs.Furthermore, the Roof Tile Roll Forming Machine prioritizes safety and user-friendliness. With built-in safety features and easy-to-use controls, the machine minimizes the risk of accidents and errors, making it suitable for operators of all skill levels. This accessibility ensures that both experienced roofers and new entrants into the industry can quickly adapt to this transformative technology.The advantages offered by the Roof Tile Roll Forming Machine are not limited to its performance alone. This innovative machinery also contributes to environmental sustainability. By optimizing material usage and minimizing waste, the machine significantly reduces the carbon footprint associated with traditional roofing methods. Moreover, the longevity of the tiles produced by the machine ensures reduced maintenance and replacement requirements, leading to long-term sustainability benefits.As the demand for efficient and cost-effective roofing solutions continues to grow, the Roof Tile Roll Forming Machine has emerged as a standout solution. Its ability to streamline the roofing process, enhance design possibilities, and prioritize safety makes it an indispensable tool for roofing contractors and manufacturers.In conclusion, the Roof Tile Roll Forming Machine has revolutionized the roofing industry by providing an efficient and precise solution for producing high-quality roof tiles. Its versatility, precision, user-friendliness, and sustainability make it an indispensable tool for modern construction. As this technology continues to grow and evolve, it is undoubtedly set to become an industry standard, shaping the future of roofing worldwide.

Efficient Glazed Tile Making Machinery for High-Quality Tiles

articlePress Step Glazed Tile Making Machinery Revolutionizing the Roofing IndustryRoofing is an essential aspect of any building, and the quality of the materials used significantly affects its durability and aesthetic value. The demand for roofing materials, particularly tiles, has been on the rise, and manufacturers have been seeking innovative ways to meet this demand. The introduction of the Press Step Glazed Tile Making Machinery has sparked a revolution in the roofing industry with its ability to produce high-quality tiles efficiently and cost-effectively.The machinery is designed to manufacture glazed tiles using a hydraulic press system, which ensures uniformity, strength, and precision. The tiles produced are of high-quality and can withstand harsh weather conditions, making them ideal for both residential and commercial buildings. The machine can produce tiles in different sizes and shapes, depending on the specifications and preferences of the customer.One of the key advantages of the Press Step Glazed Tile Making Machinery is its efficiency. The machine is fully automated, reducing the need for manual labor and ensuring consistent output. It can produce up to 20 tiles per minute, making it ideal for large-scale production. The machinery also consumes less energy, thanks to its energy-efficient design that reduces the wastage of resources.The manufacturers of the Press Step Glazed Tile Making Machinery have put safety at the forefront of the machine's design. The machine has several safety features, such as emergency stop buttons and safety guards that prevent accidents and injuries. The machine’s design is also user-friendly, making it easy for operators to use and maintain.While the Press Step Glazed Tile Making Machinery has been a game-changer in the roofing industry, it is worth noting that the machine alone cannot guarantee the quality of the tiles produced. The quality of the raw materials used is crucial in ensuring the durability and strength of the tiles. As such, manufacturers need to invest in high-quality materials, such as clay that has been extensively tested and processed to meet specific standards.The manufacturers of the Press Step Glazed Tile Making Machinery have identified this need and have developed partnerships with reputable suppliers of raw materials. As a result, they can provide a one-stop-shop for customers looking to set up a roofing tile manufacturing plant. The suppliers ensure that the raw materials supplied meet the required quality standards, thus guaranteeing the quality of the tiles produced.The Press Step Glazed Tile Making Machinery is an investment that promises long-term returns for manufacturers. The machine is durable and requires minimal maintenance, making it cost-effective in the long run. The high-quality tiles produced by the machine also have a high demand in the market, making it easy for manufacturers to recoup their initial investment.The roofing industry is constantly evolving, and manufacturers must keep up with the latest technology to remain competitive. The Press Step Glazed Tile Making Machinery has already proven to be a game-changer in the industry, and its popularity is expected to grow in the coming years. Manufacturers who invest in this machinery today are well-positioned to take advantage of the increasing demand for high-quality roofing tiles.In conclusion, the Press Step Glazed Tile Making Machinery has revolutionized the roofing industry by enhancing efficiency, safety, and quality. The machine's ability to produce high-quality tiles in large quantities has made it an ideal investment for manufacturers looking to meet the increasing demand for roofing tiles. Additionally, the machinery's partnership with reputable raw material suppliers ensures that the quality of the tiles produced is guaranteed. The Press Step Glazed Tile Making Machinery is a game-changer that promises long-term returns for manufacturers in the roofing industry.

Bag&Baggage Productions Utilizes Advanced Projector for Cutting-Edge Theater Experience

Bag&Baggage Productions (B&B), a theater company based in Hillsboro, Oregon, has recently installed a state-of-the-art projector in their new multipurpose venue, The Vault. The BenQ LK970 Blue Core Laser 4K projector was selected for its ability to project ultra-realistic set backgrounds, significantly reducing the scale, cost, and manual labor required for set designs. Aside from enhancing the company's productions and performances, the projector also allows B&B to explore creative new avenues, such as creating immersive digital projection laboratories and film festivals for area digital content creators. This is a major step forward for the company, which has been actively looking for ways to evolve and innovate in an ever-changing digital world. The LK970 Blue Core Laser 4K projector, known for its ultra-high resolution and brightness, has been used in various commercial applications such as large-scale events and museums. In the context of theater productions, it has been proven to be an effective tool for creating vivid, lifelike visual backdrops, providing an immersive experience for audiences. This innovative projection technology not only saves time and effort in making physical sets but also allows theater companies to push the boundaries of what is possible on stage. By harnessing the power of digital projection, Bag&Baggage Productions can now create unique and unforgettable productions that will keep audiences coming back for more. As a company dedicated to providing the best theatrical experiences for its audiences, Bag&Baggage Productions has taken a bold step forward by investing in cutting-edge projection technology. By installing the BenQ LK970 Blue Core Laser 4K projector, they have not only enhanced their production capabilities but also set a new standard for theater companies striving to stay ahead of the curve. In conclusion, the installation of the LK970 Blue Core Laser 4K projector by Bag&Baggage Productions is a significant development for the theater industry, showcasing the potential of technology in enhancing the creative process in a cost-effective and efficient manner. With the introduction of this technology, theater companies can now create more immersive, memorable, and visually stunning productions, setting new benchmarks for the art form. Keywords: Bag&Baggage Productions, LK970 Blue Core Laser 4K projector, horizontal barrel vault panel production equipment, theater productions, digital projection, visual display solutions, immersive experience, cutting-edge technology, cost-effective, efficient.

Get Comprehensive Roll Forming Solutions from a Cold Roll Forming Manufacturer in China

Title: Unleashing the Potential of Roll Forming Machines in Metal Roofing ApplicationsIntroduction:Metal roofing has long been a popular choice for both residential and commercial buildings due to its durability, cost-effectiveness, and aesthetics. Behind the scenes, the production of metal roofing materials has been revolutionized by advanced machinery known as roll forming machines. In this blog, we will explore the endless possibilities of roll forming machines in the metal roofing industry, highlighting their crucial role in shaping the sector's future. While focusing on the broader concepts, we will delve into the specific applications and benefits of these machines, allowing us to understand why they are considered the go-to solution for metal roofing manufacturers worldwide.Understanding Roll Forming Machines:Roll forming machines are powerful mechanical equipment designed to transform a continuous metal strip into finished products with predetermined shapes and sizes. They utilize a series of rollers and dies to progressively bend, fold, and shape the metal strip while anticipating any potential deformations, hence ensuring precise measurements and consistent quality output. This process is known as roll forming, and it plays a vital role in the production of metal roofing panels, profiles, and accessories.Applications of Roll Forming Machines in Metal Roofing:1. Metal Roofing Panels:Roll forming machines are the backbone of metal roofing panel production. With their ability to process various metals such as steel, aluminum, and copper, these machines can shape panels with different profiles, including corrugated, standing seam, and concealed fastener systems. The versatility of roll forming machines enables manufacturers to cater to diverse customer requirements efficiently.2. Panel Accessories:Besides creating roofing panels, roll forming machines are indispensable in manufacturing various metal roofing accessories. These include ridge caps, eave trims, flashing, drip edges, and gutter systems. The machines' precision and speed enable companies to produce these accessories with ease, meeting the specific design and functionality demands of each project.3. Other Metal Roofing Components:Roll forming machines can also fabricate a wide range of other key components used in metal roofing systems. These may include purlins, hat channels, framing members, and structural profiles. The ability to produce these components in-house not only offers cost savings but also ensures the compatibility and quality of the final roofing system.Benefits of Roll Forming Machines in Metal Roofing:1. High Efficiency and Cost-saving:Roll forming machines operate at impressive speeds, allowing manufacturers to produce large quantities of metal roofing materials in significantly less time compared to traditional methods. This efficiency translates into reduced labor costs, increased productivity, and higher profit margins.2. Customization and Flexibility:With the ability to adapt to various shapes, sizes, and profiles, roll forming machines open up a realm of customization possibilities. Manufacturers can easily switch between different designs, patterns, and materials, ensuring each client's unique vision is brought to life flawlessly. This flexibility is a significant selling point for metal roofing businesses looking to provide tailored solutions to their customers.3. Consistent Quality and Precision:Roll forming machines possess advanced automation features, ensuring highly accurate and consistent product output throughout the entire manufacturing process. With minimal human intervention, the risk of errors, deformations, or irregularities is significantly reduced. This results in superior quality metal roofing materials that meet or exceed industry standards.4. Reduced Material Waste:Roll forming machines are designed to maximize material utilization, minimizing waste and increasing cost-effectiveness. By implementing computer-controlled cutting mechanisms, these machines optimize the use of metal coils, significantly reducing scrap and enhancing the overall sustainability of the manufacturing process.Conclusion:Roll forming machines have revolutionized the metal roofing industry, enabling manufacturers to streamline their production processes and deliver high-quality, customized roofing materials efficiently. The ability to produce various roofing panels, accessories, and components with utmost precision, flexibility, and cost-effectiveness has made roll forming machines an indispensable asset in the sector. As the metal roofing market continues to grow, businesses that adopt these advanced machines will undoubtedly have a competitive edge, satisfying the ever-evolving demands of customers worldwide. Keywords: Roofing metal forming machine, roll forming, metal roofing panels, metal roofing accessories, metal roofing components, efficiency, customization, quality, material waste.